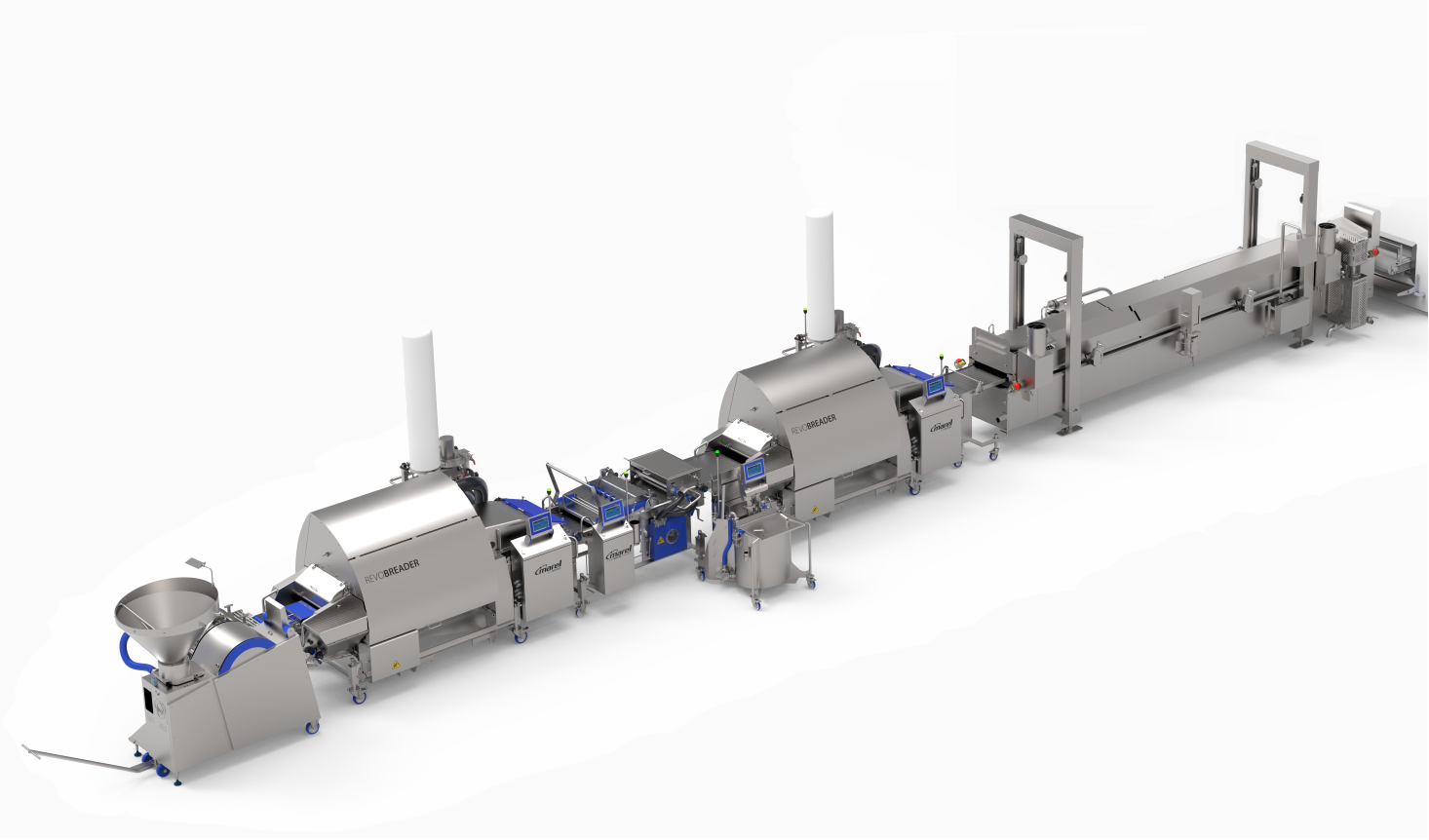

Dual mode RevoBreader

An alternative to the RevoCrumb is the RevoBreader, a flexible machine that offers a flatbed and drum mode, all in one enclosure. This dual-mode configurability is the ultimate solution for applying high-quality coating, both to home-style and flatbed coated products. Switching from one position to another is easy; it doesn’t require the removal of any machine parts and it takes less than 2 minutes.

In flatbed position, the RevoBreader guides products through a bottom bed of crumb, while covering the top layer of the product with a gently falling layer of crumb. This results in high quality, uniformly coated products. In drum position, a high pickup of crumb and optimum ‘home-style coverage of the product is guaranteed with high retention of crumb to the product during the subsequent frying and baking process. This is ideal for coating of bone-in products. In a QSR home-style production run, the drum of the RevoBreader completes the coating process. The result is a home-style crumb with a handmade look, a breading with a highly attractive appearance, perfectly suited for sale in QSR restaurants.

Production insight

For a centralized process control solution, the Marel’s new convenience line is backed by Innova Food Processing Software. By controlling and monitoring the recipes and production, Innova ensures that the end product aligns with the customers’ orders. The supplied real-time data for performance monitoring ensures better food quality and food safety.

Innova’s full traceability program provides an overview of the raw materials' journey through the processing plant. As a part of this, the traceability engine records every process step in the convenience line. Together with the Recipe Manager tool, it’s easy to track systematically what has been made, when, where and by whom.