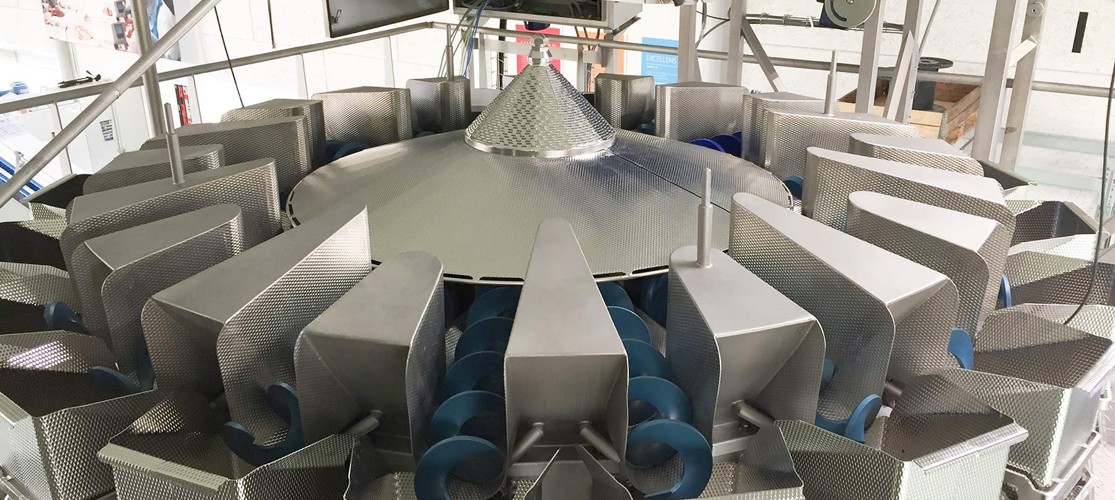

The Multihead Weigher Large features bigger screws and larger pockets, while all other parts are also bigger and wider to handle large chicken meat pieces. The capacity is 10 tons an hour. The MHW can also handle smaller pieces such as wings, thighs and drums. For giblets such as hearts and livers, a smaller MHW is, however, more suitable. The MHW Large uses the same software technology as existing, smaller family members. In theory, the multi-job software of Marel’s MHWs can execute six jobs simultaneously. In practice, three jobs at once will be the maximum for most processors. An example would be two retail tray-packing jobs and one export box packing task.

Fewer products to make a batch

This Multihead Weigher with 20 large hoppers really shows its abilities when dealing with large products. In this case, only 2, 3 or 4 of such large pieces will be necessary per retail tray pack. This makes the batching job more challenging, but the Multihead Weigher Large can do it. Quite simply, there are fewer pieces with the desired weights to choose from when assembling fixed weight batches. The upstream process must, therefore, be involved in regulating the infeed. Only those legs fitting within a certain weight range should be fed to the MHW. This can be done because the products will have already been weighed in the shackles. It’s a question of selecting a certain variation of weights and run this batch to the MHW. The other legs can go straight to the bulk packing area without passing through the MHW.