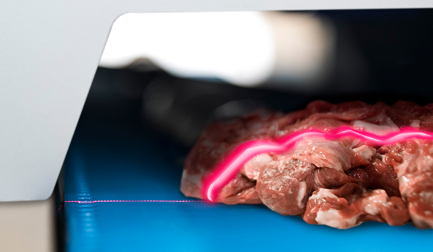

Unlike other X-ray inspection systems, SensorX Magna is strategically located where it has the most impact - at the start of the processing line. It automatically detects and rejects bone from the incoming meat supply right from the start, before grinding even begins. This allows improvements to the grinding and mixing process that simply have not been possible before.

7 ways SensorX Magna revolutionizes the meat inspection process

With its unique features, SensorX Magna trim inspection system is a real game-changer for X-ray bone detection and fat analysis

Processors who perform high-volume mixing and grinding to create meat products such as burgers and sausages face an extremely competitive marketplace. It is essential to consistently offer the highest quality products that meet the most stringent food safety requirements. At the same time, it is vital to protect margins, saving on material costs and streamlining processes. Find out how SensorX Magna X-ray inspection system transforms meat preparation to help processors deliver on these challenges.

1. Eliminate bone before grinding starts

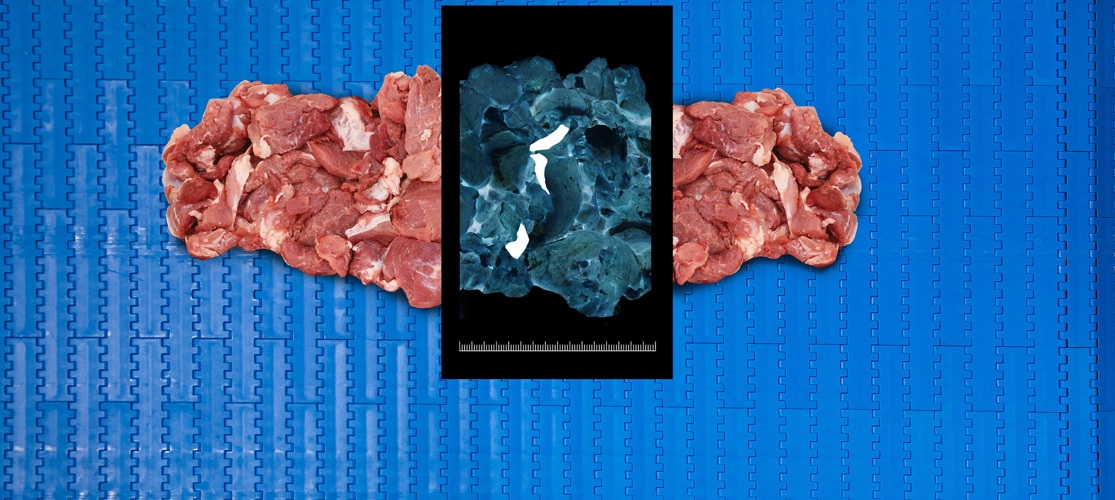

2. Remove bone without destroying yield

Finding bone and other hard contaminants, such as metal and glass, is only half the battle – how you remove them makes all the difference. SensorX Magna is the only X-ray inspection system on the market that can efficiently reject bones from the meat supply without compromising yield or throughput. It makes bone removal a manageable, streamlined part of the grinding and mixing process.

What really sets SensorX Magna apart is its powerful combination of industry-leading bone detection, and state-of-the-art reject mechanism. It uses advanced X-ray technology to detect bone with unmatched accuracy. It then automatically rejects it with less meat than any other comparable system. A segment weighing just 1.5 kg (3 lbs) is cut from the product stream compared to the average 10 kg (20 lbs) removed by traditional X-ray systems. The segment is then rerun through the system so that only 0.3 kg (0.5 lbs) of meat is ultimately rejected with each bone.

3. Measure chemical lean from the start

Typically, processors achieve their target fat to lean ratio by manually measuring the chemical lean (CL) of the supply offline after grinding and mixing. Depending on the result, the mix is then adjusted. This is extremely time-consuming, and the risk of human error is high.

SensorX Magna uses industry-leading X-ray technology to efficiently and accurately measure the CL of the incoming meat supply before grinding and mixing at full production speed.

4. Control fat to lean—control profit

Gaining control of raw material CL is an essential step to ensure quality end products. Measuring CL of the incoming meat gives a level of control over blending fat and lean meat that was previously just not possible. SensorX Magna makes it possible to create the correct CL of the final batch right from the start of processing. This ensures production is streamlined, running at full capacity with the highest accuracy. Processors can also be confident right from the outset that their end products will be on spec and that raw material is being used in the most cost-efficient way.

5. Automate trim standardization

The trim standardization process can be fully automated by combining SensorX Magna with additional Marel equipment and Innova Food Processing software. This gives a simple and highly effective way to ensure standardization of a batch to a set fat and weight target based on a customers’ product specifications.

6. Protect and enhance your company name

Customers increasingly want firm assurance that the products they buy are of the highest quality. SensorX Magna provides a guarantee that products will be consistently bone-free, with a CL that’s on target and that required food safety standards are met. It also has full traceability functionality, which ensures action can be taken quickly to minimize the size of recalls, tracing every product back to its source to protect customers, consumers and safeguarding your company’s reputation. Providing this level of assurance helps maintain the trust and loyalty of existing customers. It can also be a crucial factor in securing new business. In addition, the SensorX Magna helps to virtually eliminate customer complaints and recalls.

7. Benchmark suppliers

Processors typically buy their meat from multiple suppliers. Unfortunately, they sometimes don't get the quality that they pay for. This can present enormous challenges when processing high volumes as it is hard to guarantee consistent raw material will go into the production process.

Supplier monitoring software is an integral part of SensorX Magna. The system monitors all incoming meat to determine the true CL value and detect contaminants, helping processors ensure supplies meet specifications. If raw material is not up to scratch, a claim can be made for compensation. Having a clear overview of the exact number of contaminants in each batch received, as well as precise CL levels, also allows processors to benchmark their suppliers and make strategic, data-driven purchasing decisions, reliably selecting the suppliers who will consistently provide the best quality raw materials.

Your partner for maximizing value

X-ray inspection is a critical first step for creating quality meat products such as burgers and sausages. Marel provides solutions that offer superior bone detection and CL analysis, helping processors maximize the value of their raw material through the use of cutting-edge technology.

Find out how Marel's SensorX Magna can help you create superior meat products such as burgers, sausages, minced meat and meatballs.

Contact a Marel specialistNews

Get in touch

Our dedicated team is here to help and answer any questions you may have. Please complete the form, and we’ll get back to you as soon as possible. We look forward to hearing from you.