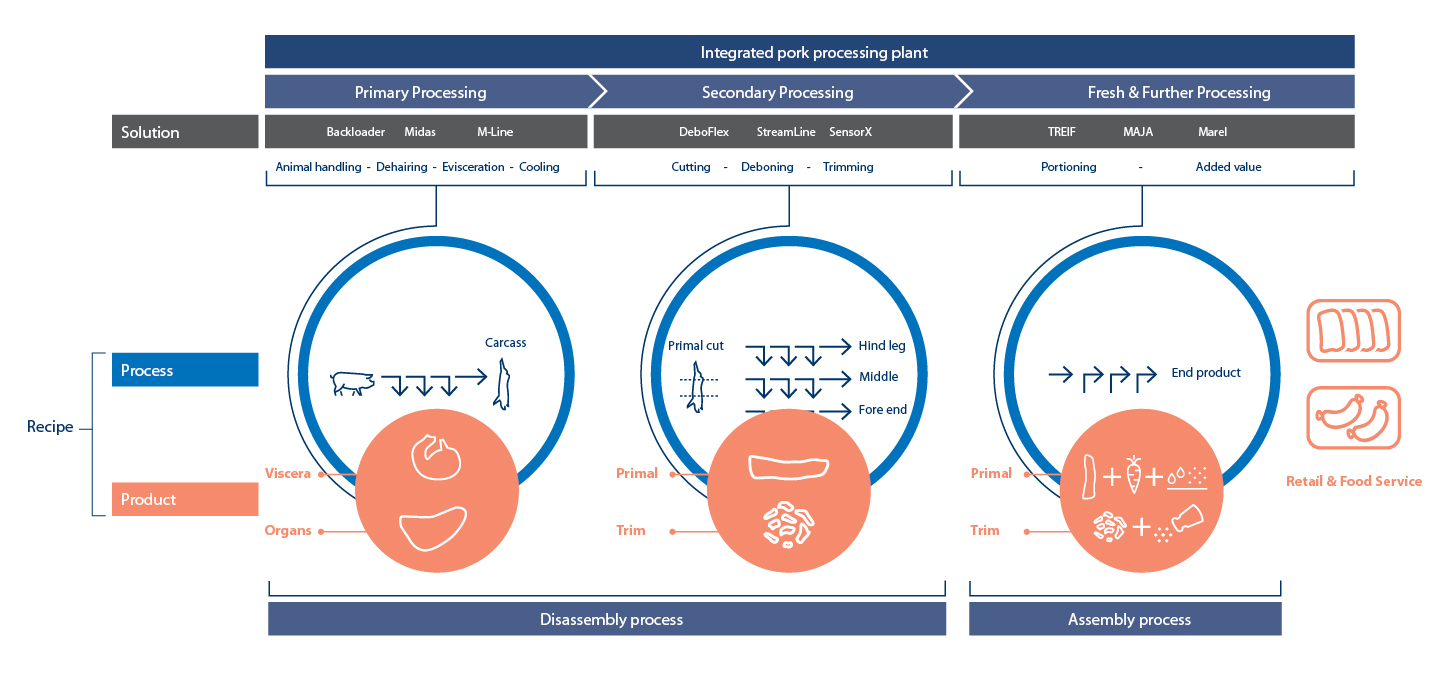

Let’s unpack product-process-solution a bit more and later, explore an example of the approach in action.

Three elements to a flexible and profitable facility

- The product

What are the end products you produce today and what do you wish to produce in the future?

By clearly identifying your input and output product mix at the beginning of the design process, you create a solid foundation which will result in a processing facility that meets your long-term goals. A few questions we consider:

- What is your focus market? Domestic and/or export market, retail or food service, fresh or processed end products.

- What specific final products do you need to produce?

- Do you need the flexibility to switch between different product outputs?

- The process

What is the most efficient way to transform your input product into the desired end products?

This step is to define the most efficient way to process your chosen product mix. Every step in your processing affects your yield, labor costs, and downtime to a different degree. By reviewing each process, we highlight areas that work well and where there are bottlenecks.

- Tasks – defining the specific actions required.

- Work order – establishing the correct sequence of tasks to ensure efficiency and consistency.

- Capacity – determining the required throughput to meet production demands while maintaining quality and yield.

It is at this stage we begin to explore how changing elements such as levels of automation will affect bottlenecks and address other challenges.

- The solution

Choosing the right technology to meet product and process goals.

Now the product mix and process are clear it’s time to choose the solutions which will most effectively achieve your goals. A solution is more than just equipment or software, it determines how flow, automation, and control come together to create an efficient production line.

The right solution supports the required level of automation, provides scalability for future product variations, optimizes flow and minimizes inefficiencies.

In this step we consider:

- Flow/logistics – ensuring smooth movement of products with minimal handling costs and downtime.

- Automation/robotics – reducing manual labor while maintaining precision and efficiency.

- Control/digitalization – providing real-time monitoring and optimization for better decision-making.

An example of the practice in action

What does this look like in practice?

Our example is a pork processor who wants to address their labor shortages and inconsistent quality in their fore-end processing line.

The first step is to investigate the product range and different processes currently in place and unpack the challenges they need to address along with their processing goals — immediate and futuristic.

The challenge: deciding how to process the fore-end efficiently while balancing yield, automation, labor, and cost.

- Defining the product mix: input & output

While the current product mix is known, at this point we also consider future goals such as increasing output, adding to the current range, expanding into new markets. Our processor is a domestic supplier but wants to expand into the export market.

- Process considerations:

- What is the current process? (tasks, work order, capacity)

- Where are the bottle necks?

- What are the challenges? (labor scarcity, losing valuable meat during deboning, inconsistent end-product quality, minimal product visibility)

Looking at their current processes in combination with challenges and/or processing goals we can start to explore options:

- The solution:

- What equipment options are available?

- Automation vs manual levels:

Where will automation make the biggest difference: loading fore-ends onto carriers, deboning, inline deskinning, deboning, automating removal of shoulder blades and shoulder. How many workstations are needed to meet capacity and what is optimal support of workplace health and safety.

- Software

The processor wants to improve their production oversight and control to improve worker performance and productivity. As they expand into export markets, they will need to increase traceability to meet international regulatory requirements. Easier reporting and auditing would be a benefit.

- Future-proofing

The processor wants to start small and increase their automation as their business needs grow. It is important to choose a solution that is flexible to meet any future needs.

By adopting a modular approach, the processor can gradually scale automation without a high initial outlay. With a flexible solution, they can adjust the design to meet end-product goals. Changing automation levels based on labor availability.

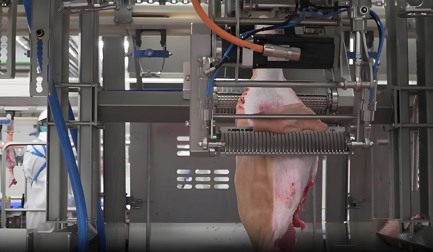

Our example processor has opted to start their automation journey with the DeboFlex for fore-ends. The hanging conveyor system minimizes worker injury and the need for specialist knowledge, automates several deboning tasks and improves production flow.

It meets their immediate challenges of skilled labor shortages, improves end-product consistency and minimizes product loss from inaccurate deboning.

After installation our processor noticed a significant increase in yield, improved production flow and greater worker satisfaction. There were two unexpected benefits, the adjustable ergonomic workstations and the single task actions provided by the DeboFlex increased their workforce pool, reducing labor scarcity. While the changed workflow and modular design freed up valuable floor space allowing for future expansion in the same facility.

The future is already here

The success of today’s pork processor depends on an ability to adapt to challenges and optimize raw materials. Advances in pork processing technology are perfectly timed to help shift the industry into future growth by offering a way to gradually increase automation to control costs and protect margins. While keeping businesses flexible to meet changing product demands.

JBT Marel’s product-process-solution approach to addressing challenges ensures processing solutions are tailored to your exact needs, providing scalability and efficiency without unnecessary complexity.

If you’re looking to increase profitability, now is the time to evaluate how your product mix, process, and solutions align with your long-term business goals.

Are you ready to discuss how you can configure the right processing solution? Let’s connect.