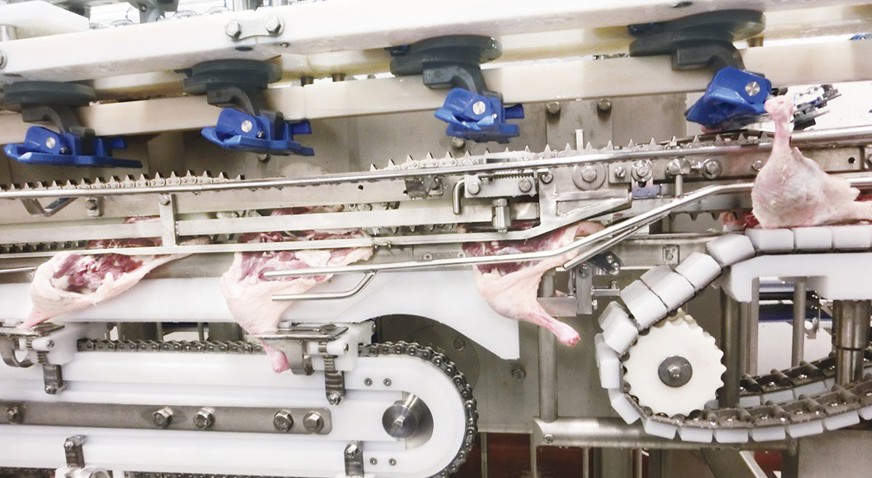

Marel is able to offer duck processors an automatic modular in-line cut-up system capable of handling up to 6000 ducks per hour (100 dpm) of up to 2.8 kg (6.2 lb) eviscerated weight. The ACM-NT system, developed specially for ducks, is the only one of its kind currently on the market and will handle both air and water chilled products. At this moment the new system is in successful everyday operation with duck processors in Australasia, the British Isles, Russia and Central Europe.

Flexible, modular and precise

ACM-NT uses the unique Sigma overhead conveyor; its layout is infinitely flexible. Systems can be configured to suit the exact processing and layout requirements of each individual plant. A combination of the unique ACM-NT shackle and turning mechanisms within the system allows products to be held and positioned perfectly for each cutting operation, resulting in optimum yield as well as top presentation and quality. The system is fully modular. If and when processing requirements change, modules can be moved or added.