We decided to install the RevoPortioner 1000 because there are very few forming machines on the market that can meet our production requirements.

Sustainable processing

0.3%

Minimize waste

40%

Reduce resources

0%

Eliminate water

The new RevoPortioner 1000

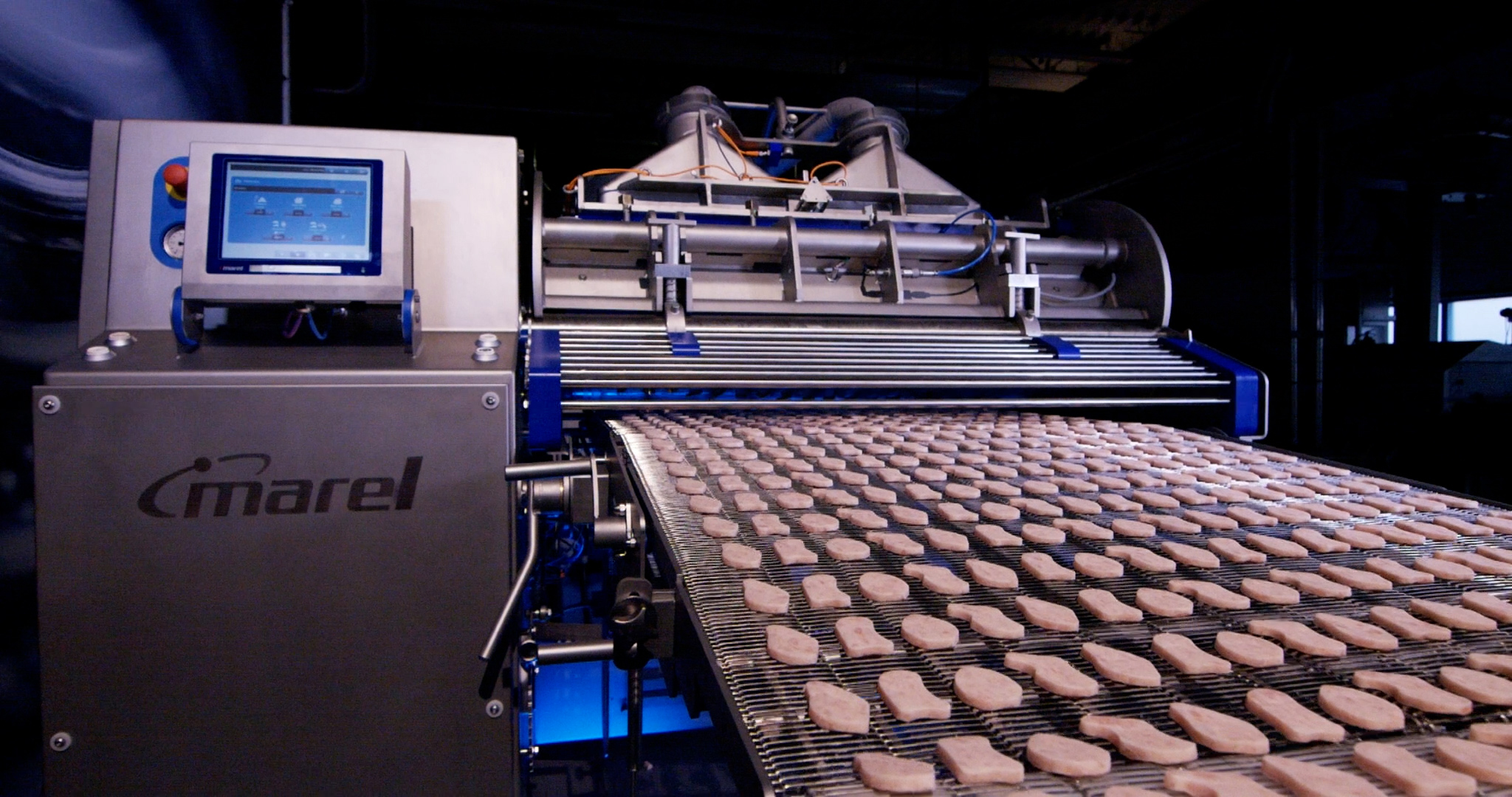

For processors who want to increase output as well as product quality, the RevoPortioner 1000 is the perfect solution. Whether you’re forming chicken nuggets, hamburgers or patties made with alternative protein, the RevoPortioner 1000 builds on the proven technology of previous generations, and incorporates innovative new features, to offer a significant increase in volume with an unrivaled consistency in product shape and weight.

Download our playbook to get an insight into how the low-pressure forming technology behind the RevoPortioner 1000 can help you create superior convenience products.

Sustainable processing

0.3%

Minimize waste

40%

Reduce resources

0%

Eliminate water

Increased volume and speed

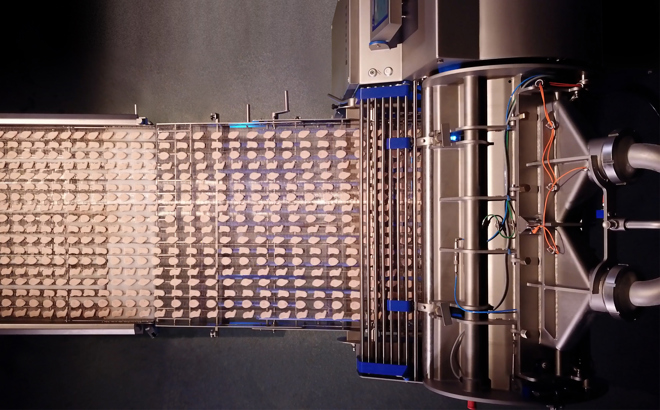

The RevoPortioner 1000 now has a 1000 mm (40’’) forming width and an improved maximum speed of 40 m/min. These factors combine to increase output significantly.

For processors manufacturing convenience products such as burger patties and chicken nuggets, the RevoPortioner 1000 offers the added benefit of an extremely low footprint, compared to previous solutions with similar capacity.

Unique distribution design

Building on the performance of previous models, the RevoPortioner 1000 now has a new and improved distribution manifold. This, combined with the patented shoe plate pressure zones, gives a more robust system with optimal control of the meat mass across the width of the forming drum. The highest levels of product consistency and weight accuracy are always ensured.

Unrivaled air-release function

An improved air-release function gives the RevoPortioner 1000 an unmatched ejection performance. A redesigned delivery method optimizes the air pulse that discharges products from the forming drum. It gives an enhanced release and maintains product integrity better than any comparable equipment on the market. This unique function also guarantees 16 hours of high-level performance with just one drum.

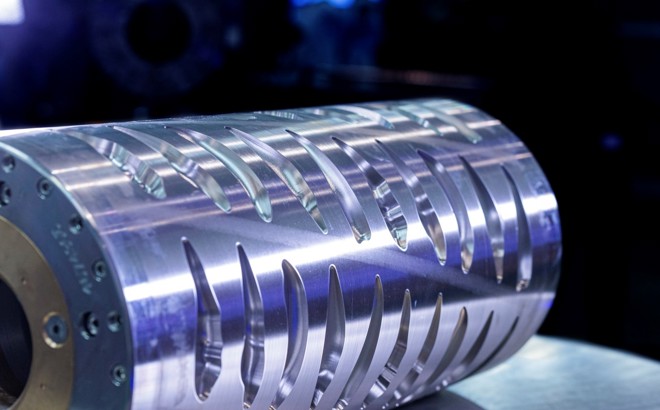

Unique Helix Drum technology

The RevoPortioner 1000 continues to use the proven Helix Drum technology to increase capacity and product quality. Product shapes are aligned diagonally to enable a continuous filling process in which the pump does not need to start and stop as frequently as with conventional drums. This leads to a more constant meat flow in the system, helping to control the filling pressure and eliminate variations and at the same time increase capacity. As well as this, operating costs are lower as maintenance costs are decreased due to less wear and tear.

We decided to install the RevoPortioner 1000 because there are very few forming machines on the market that can meet our production requirements.

Juergen Wehner

Plant Manager OSI Food Solutions

Every day, convenience food processors around the world benefit from the innovative forming solutions we’ve been developing for more than 25 years. With the introduction of the RevoPortioner 1000, Marel now has the most extensive range of low-pressure forming equipment on the market. Whether you are forming chicken, pork, beef, fish, plant-based protein, potato or pet food, we can create a full food processing production line to meet your needs.

Prepared foodsOur dedicated team is here to help and answer any questions you may have. Please complete the form, and we’ll get back to you as soon as possible. We look forward to hearing from you.