Information

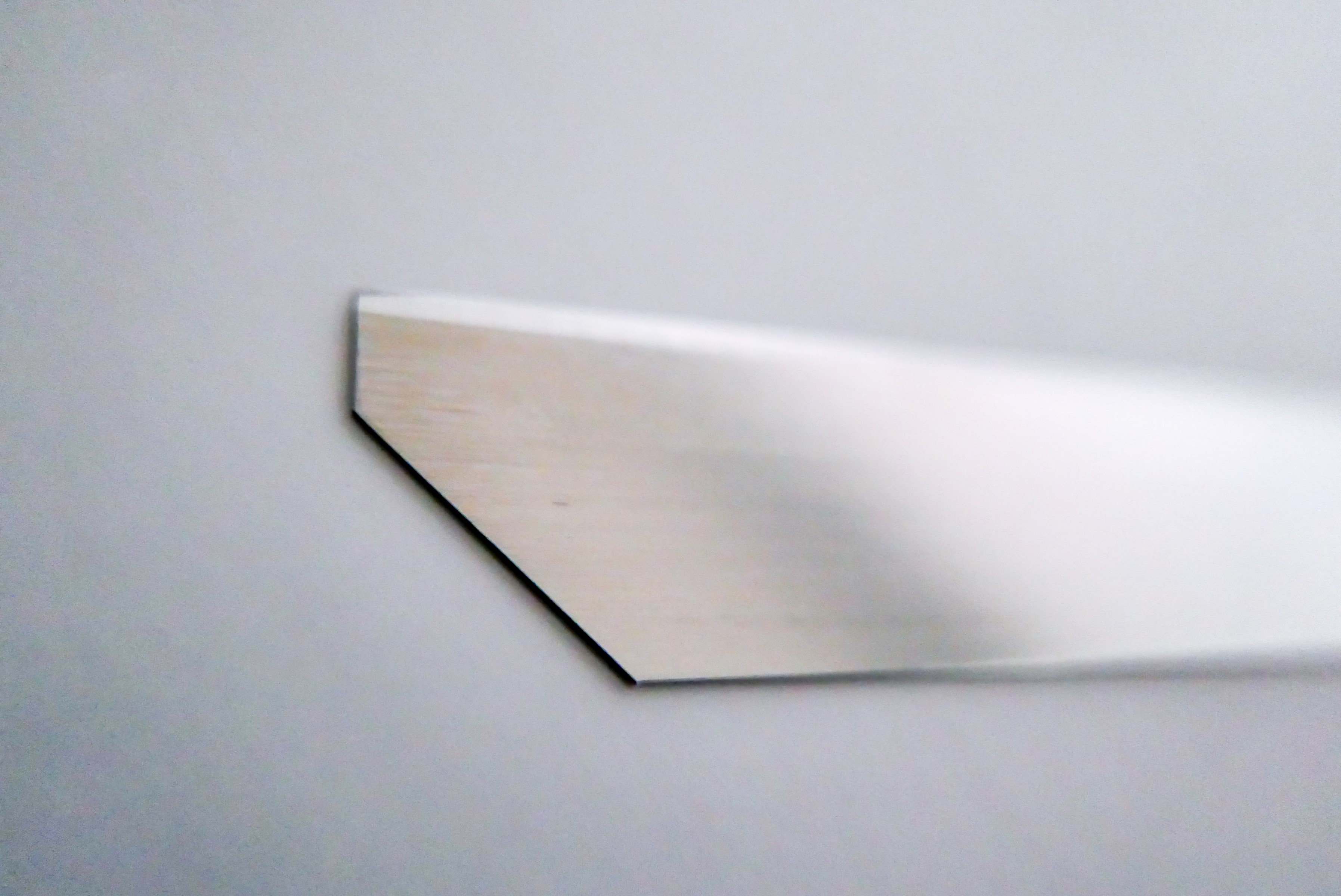

The 6000DHT Loin Trimmer is designed to remove fat and skin from loins. An overall safe and robust design provides consistent yields and high-quality end products. The versatility of this machine allows it to work with beef strip loin and bone-in pork loins.

Features

- Available in right- and left-hand configurations

- Market-leading accuracy and throughputs

- Improved yields

- Reduced labor and higher-quality end product

- "Line bored" cabinet creates a perfect alignment between tooth roll and skinning mechanism

- Shoe remains on the machine during sanitation to prevent damage

- Drive belts located on one side for easier maintenance

- Adjustable height exit conveyor is ideal for a multitude of production line layouts

- Open design for easy maintenance and sanitation

- Low cost of ownership

- Easy to lock down top feed mechanisms

- Unique machine designed for specific processing of beef strip loins and whole bone-in pork loins

- Easy to operate push buttons for adjustments for high-quality end products

- Heavy gauge structure resists damage and requires less maintenance

- Sealed cabinet improves sanitation, protects parts, requires less maintenance with less cleanup cost.

- Keyed side panels provide easy and quick access to electrical and mechanical components, reducing downtime

- Swivel casters make it easy to move around for cleanup and maintenance

- Heavy duty interlock belting for longer life span even in bone-in products, improved sanitation, and easy repair or replacement

- Delrin rail supports improve sanitation and makes for smooth operation

- Machine disassembles quickly for easy cleaning and maintenance

- Built-in storage for all removable parts

- Interlocked hood and guards prevent access to moving parts