Information

Industry-leading skinning performance

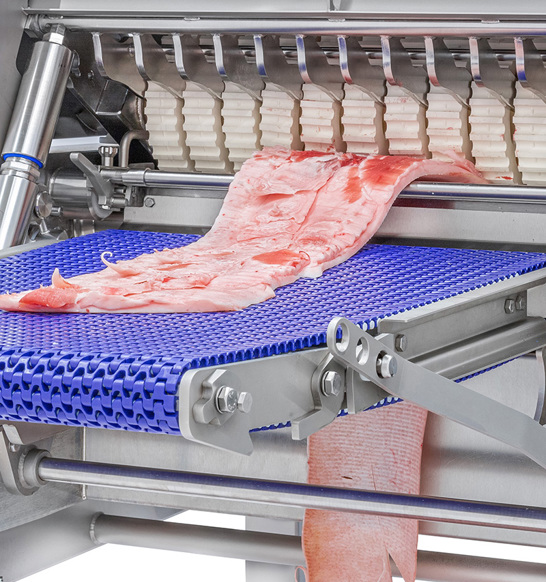

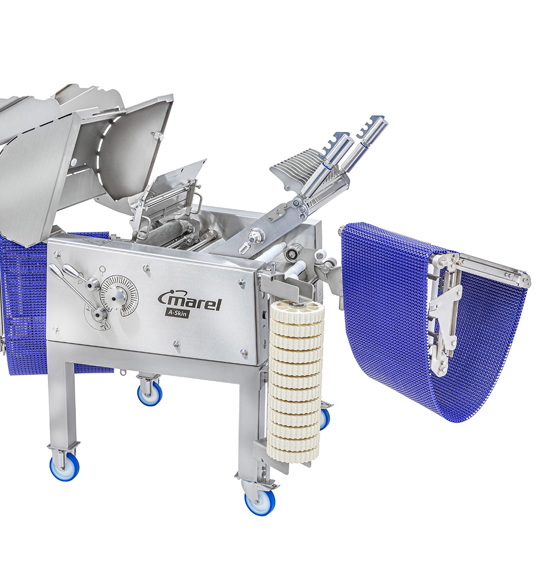

The A-Skin is a fully automatic derinding skinner that allows you to level up your deboning line and makes it fit for the future. It is a modular platform and thus a highly logistic solution that enables individual configuration and sets safety, hygiene, and yield standards to cater to your industrial skinning requirements. Unique features, such as the bypass function and the cantilever belt mechanism, offer highly flexible use of the machine and unmatched serviceability and hygiene conditions.

Wide operational window

Available in three cutting widths, the A-Skin is an ideal derinding skinner for medium-sized processors and big industrial players that need a solution that performs exceptionally in a wide variety of applications and specific customer layouts, and can withstand high throughput in an industrial environment. It is suited for fully automatic derinding of all fresh cuts of pork, e.g., belly/belly dewlap, back and neck fat, cheek, shoulder and ham topside, boneless pork shoulder (also with boned knuckle), boneless pork ham and without topside.