Information

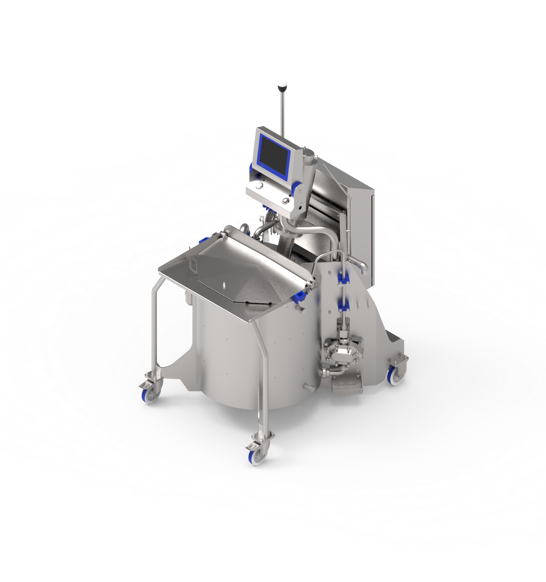

Precise mixing starts with Marel’s Active Mixer. This semi-automatic mixer takes powder and water and turns it into a homogeneous mixture, which can be tempura or a lower viscosity batter. Its adjustable design ensures that the right amount of force is used to make a lump-free batter within 2 minutes.

Recipe management ensures a consistent batter

The Active Mixer is fitted with a recipe management menu that saves recipes centrally for a simple and repeatable process. When empty, the mixer automatically fills with the set amount of water. On the screen, the operator can see which actions are required from him, such as the amount of powder he needs to add. The Active Mixer gives real-time feedback on the batter’s viscosity and if this does not match the recipe settings, a warning light will give a signal. This guarantees a very repeatable and reproducible, worry-free process.

Semi-automatic process minimizes labor

When the mix is ready, a pump transfers it to the connected batter or tempura applicator. The mixer maintains the desired level of batter or tempura in the applicator using an adjustable level sensor. The mixer agitates the mix intermittently between two mixing cycles to ensure homogeneity. When the mixer is empty, the mixer automatically fills with water and signals the operator to add powder. This significantly reduces the required amount of labor in the mixing process.

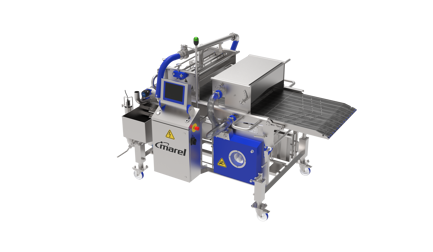

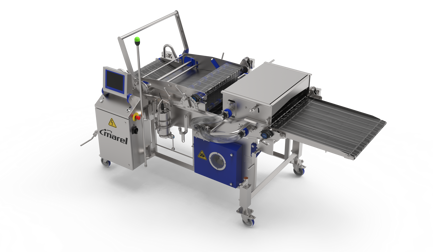

Active Feeder improves end-product consistency

By expanding your Active Mixer with an Active Feeder, the correct amount of powder is added to the mixer automatically. Precise measurements are ensured every time, guaranteeing every batch of has a consistent water-to-powder ratio. This enables processors to create a batter or a tempura with a consistent viscosity. The Active Feeder increases throughput and line efficiency and reduces operator dependency.