Information

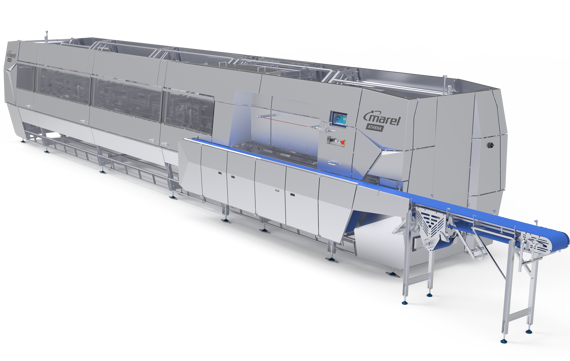

This fully automated process can handle the widest range of chicken breast weights at a speed of 6,000 per hour. Compared to other breast deboning equipment, ATHENA is distinguished by its yield, productivity, remote digitalized control, individual adaptive process, intelligent software and automatic harvesting.

Labor-saving

When products from the ACM-NT cut-up system come via the Breast Cap Positioner, they arrive uniformly singulated, so that no additional labor is required to position the breast caps. Now, only two operators are needed to put every breast into the loader, an ergonomically convenient and easy operation with no force required. It’s the automated loading system that puts the breast onto the product carrier.

At the end of the deboning process, diabolos effectively harvest the fillet from the carcass, saving several operators. ATHENA carefully positions fillets onto a conveyor for singulated presentation to downstream processes such as weighing, vision grading, inspection and portioning. Therefore, no operators are needed for manual singulation. Finally, ATHENA's data-driven approach drastically reduces the need for manual trimming.

Automatic adjustment

With fewer staff available to the plant, it’s convenient that ATHENA doesn't need adjusting during operation. The system doesn’t have any external hand wheels, levers or other mechanical tools. All settings are automatic or electronic, and data-driven.

Operating the ATHENA is easy via the intuitive HMI touchscreen. A single touch automatically sets the modules to adapt themselves to the expected weight of the incoming flock of products. These recipe settings will correspond to the different types of products, whether these be regular broilers, local or organic chicken. In addition, the PMD measuring module determines the size of each individual breast cap. Using this data, the settings of downstream modules are automatically fine-tuned to each individual breast cap. In this way, ATHENA can easily handle in-flock breast cap variations.

Modules

After the PMD measuring unit, the modules begin their work. Skinning, wishbone removal, trimming, separating, halving and harvesting are among the operations ATHENA performs on butterflies and breast fillets. When tenderloins are harvested separately, consecutive modules for separation, membrane incision and harvesting are activated. By-products such as baby tenders and eye meat can also be harvested, either as separate products or attached to the main breast meat.