Information

Flexible all-in-one solution

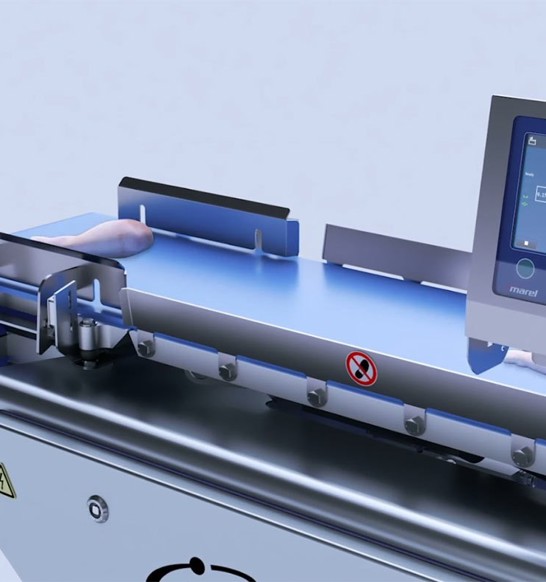

Marel’s Compact Grader is designed to fulfill the needs of smaller operators and larger ones when requiring an excess capacity to handle temporary or seasonal overflows.

It consists of an infeed section, dynamic weighing and discharge with optional grading and batching processes for catch-weight and fixed-weight batching.

The Compact Grader will handle many poultry products, fresh or frozen: whole grillers, front halves, saddles, butterflies, split breasts, whole legs, thighs, drums, whole wings, breast fillets, leg meat and thigh fillets.

Featuring a wide belt and high throughput, it can grade product of up to 3 kilos [6.6 lbs] weight.

From grading to batching

When optional automatic batching bins and tables are added to the system, the Compact Grader becomes a batching solution that ensures best fit batching with minimal giveaway. Timely opening and closing of the batching bins is needed to keep batches of products together. For this, operators are supported by a batching light button on the bin. This process provides maximum throughput and doesn’t waste any time.

Advanced technology

Plug and play software is included. Processors can make the most of their Compact Grader right away, setting up multiple programs and monitoring the process. The user-friendly graphical interface of the M2400 display can control more than 50 grading programs. Connection to Innova Food Processing Software gives access to continuous data collection, real-time monitoring, easy-to-understand reporting and traceability throughout the process.

Plug and play

The Compact Grader is easy to install and operate. It includes a dynamic weighing platform that filters out disturbances and automatically adjusts the weighing process.

Thanks to its telescopic legs, the Compact Grader is adjustable in height, so that good working ergonomics are always guaranteed.

The Compact Grader comes in three versions, each with its own capacity and maximum product size. There’s also a choice of the number of gates, 2x3 or 2x4 gates.

Hygienic and robust design

To meet the most stringent food hygiene requirements, the Marel Compact Grader allows for trouble-free and effective cleaning. Smooth, rounded edges minimize areas where food can trap. The Compact Grader is also designed to withstand the high-pressure washdowns of the food processing environment. The Compact Grader is built to maximize operational efficiency and equipment uptime.

- Simple installation - "plug and play"

- Gentle product handling

- M2400 easy-to-operate indicator

- Available with various accessories

- Integrates with Marel's production software Innova