Information

Marel Poultry offers the most efficient solution to upgrade drumsticks into delicious fresh, deboned products. As a tasty base material for ready-made products, deboned drumstick meat adds more value than its bone-in form.

Labor saving and flexible

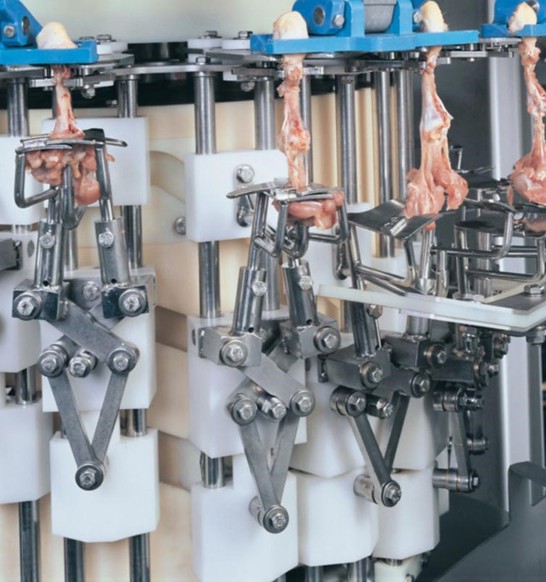

The dedicated drumstick deboning system integrates in the ACM-NT system, where virtually no human intervention is needed.

Automated drumstick deboning gives plant management much more flexibility to debone or not; all that is needed is to simply press a button.

How it works

Once thigh meat has been harvested, it is time for drumstick selection. Non-selected drumsticks will be packed bone-in on trays. Selected drumsticks are automatically transferred to a dedicated ACM-NT line to be deboned.

In the process, several incisions are necessary to loosen the meat around the bone and make subsequent processing possible. Once deskinned, the meat is scraped down the bone and harvested. While the bone stays in the shackle, the drumstick fillet is collected on a conveyor underneath, ready for further processing or packing.

- Products stay inline in the ACM-NT shackles

- Flexible choice for deboning or not

- Easily engageable and disengageable

- Different modules for incisions, deskinning, deboning and harvesting

- Perfect meat for kebab, barbecue skewers, nuggets, burgers, patties and schnitzels

- Larger surface area to marinade

- Capable of handling all capacities, up to today’s highest speeds

- Stable performance within a wide infeed weight range

- Human labor hardly needed

- Worry-free operation

- Easily adjustable controlling