Information

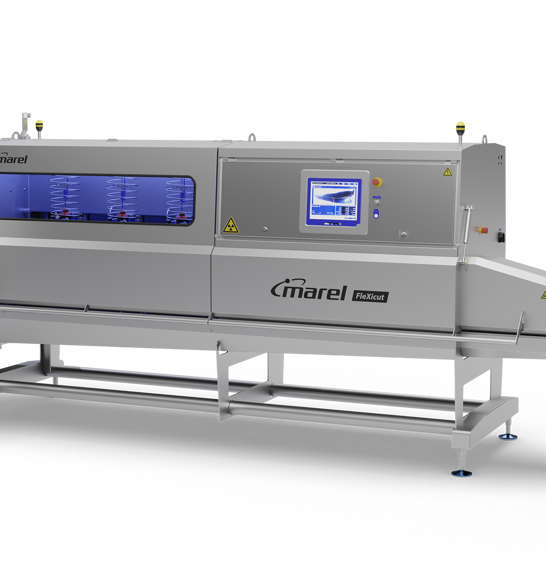

Superb performance with X-ray bone detection

As fillets pass through the 300mm wide X-ray scanner, a high-resolution X-ray locates bones as small as 0.2mm, while a 3D vision scanner accurately measures individual fillets.

The FleXicut Tres provides incredible cutting flexibility in skin-on and skin-off portioning using dual technologies of three water-jet robots and twin cutting blades.

Water-jet robot cutters and twin cutting blades operate in tandem to increase portioning flexibility with multiple cutting abilities. Intelligent software analyzes the X-ray scans and automatically adjusts cut angles to the shape and thickness of each fillet to ensure precision bone removal and portioning that minimizes raw material cut-off.

The three water-jet cutting robots remove pinbones and make curved and angled cuts, while the twin blades make vertical cuts according to predefined cutting patterns, specific weight, length and shape.

Preprogrammed cutting patterns focus on high-value portioning improving fillet utilization for processors of large whitefish and pre-rigor salmon fillets.