Information

Applications

The conveyorized MAJA ESB 4434 Whitefish Skinner is exceptionally safe and ideal for yield-oriented skinning e.g. of fresh fillets from cod, saith, haddock and similar species.

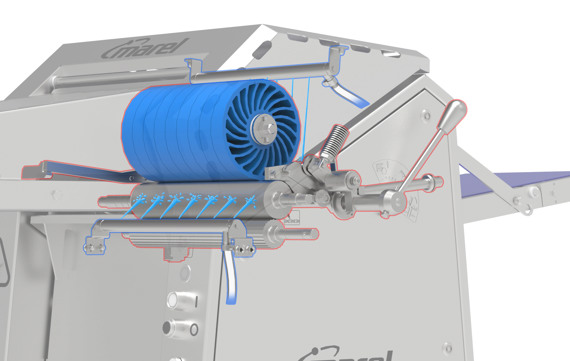

Cut control for perfect skinning

The automatic cut control guarantees a perfect start to the skinning process in automatic in-line operation, leaving no skin on the fillet. With virtually no manual post-processing needed, processors save time, reduce labor costs and improve product hygiene.

Easy operation

- Quick machine start up with a simple ON/OFF switch

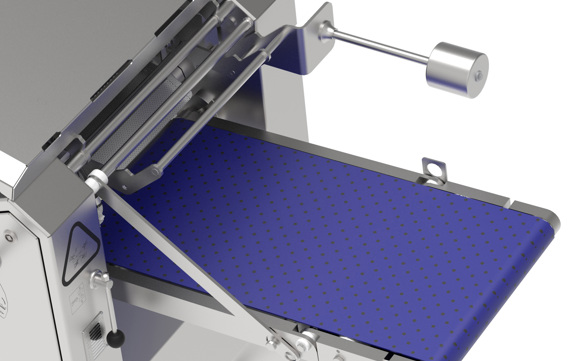

- Skin thickness can be adjusted individually using the lateral adjustment lever

- The fish skinning process is safe and easy, requiring no training

Gentle pressure

The special top feed rollers gently push on the fillet. Pressure can be adjusted by a contra weight system, where the height of each fillet is taken into consideration.

Water spray option

If necessary, the water spray devices can be switched on to wash away skin waste from the skinning area. Keeping the tooth roll clean, and to improve the outfeed of the fillets.

Features

- Durable, hygienic, easy-to-clean machine design

- Easy and time-saving cleaning make the machine exceptionally sanitary. All machine parts that need to be cleaned can be removed

- Cleaning water drips easily off the chamfered steel surfaces, preventing residue from water, dirt, or cleaning agents

- Embedded and sealed lateral panels mean that no dirt can enter the machine housing

- The completely sealed motor housing protects the motor from splash water and dirt

- A seamless shape without screws in the food area makes it easy to clean and prevents accumulation of meat particles and any kind of contamination

- All machine parts are made from food-safe material

- The machine housing is made from 2-10 mm stainless steel plates. This solid construction maintains the machine’s value

- Producing a long lifecycle with reduced maintenance and low costs of ownership