Information

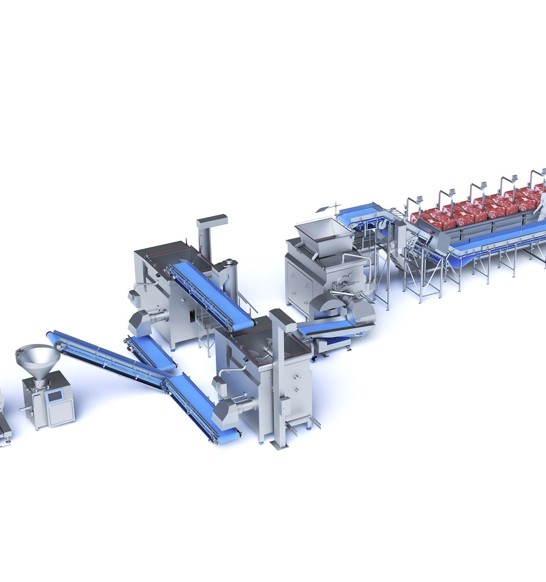

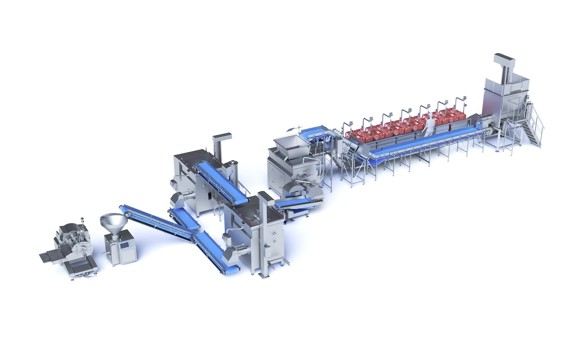

Our full-line solutions with high-quality mixing and grinding machines help you to prepare your meat for the best possible meatball production. The fully automated line prepares your meat mass to a required recipe and uniformly mixed, ideal for the best possible shaped meat balls.

In the production of meatballs, it is vital that each batch is at the right temperature and has precisely the right fat content. Our integrated online fat analysis simplifies measuring and achieving the best possible shape for optimal cooking with maximum yields. Our square intermeshing mixers ensure uniformity of the finished product. This technique promotes faster, easier absorption of seasoning and other additives, and reduced mixing time that minimizes the risk of smearing. CO2 may be added to achieve the correct temperature for the forming process.

Our meatball production lines give you optimum control of the finished product and full traceability through each individual part of the process.

We are at your disposal to provide competent advice when it comes to the optimum composition of batches to harmonize with different forming and cooking methods.