Information

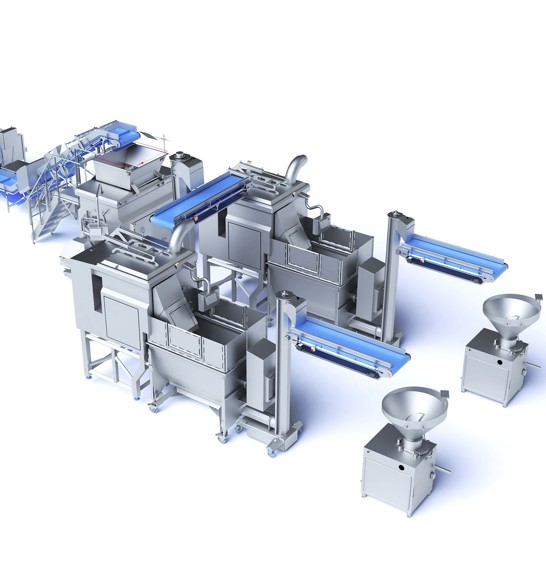

Preparation from A to Z

From highly efficient grinding and mixing through precision online fat analysis, all the way to the case-ready poultry meat portion. We’ve got every step in the preparation process covered. We work with you to create a fully connected system, tailored to your specific requirements, ensuring you create a consistently superior poultry meat mass whilst minimizing giveaway and maximizing yield with accurate online fat analyzing.

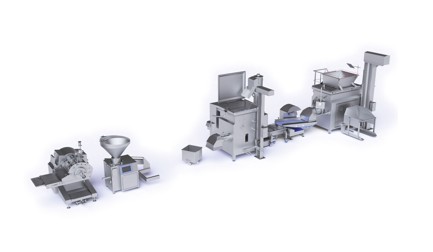

Efficient and profitable grinding

Our grinders are manufactured to handle extremely high capacities of both fresh and frozen meat. Their unique design ensures consistent flow out of the grinder with less back wash, protein destruction and minimal temperature increase.

Precision fat analysis

Our preparation line has fully integrated online fat analysis, based on contact-free technology, which measures the fat content of the meat as it leaves the grinder at capacities of up to 20 tons/hour. Using unique spectroscopy technology, incoming raw material is analyzed and the fat percentage is calculated, helping you to deliver superior quality minced poultry products with the highest levels of consistency.

Standardized mixing

To ensure quick, gentle, homogeneous mixing with highest hygiene standards, we have a comprehensive range of industrial mixers.

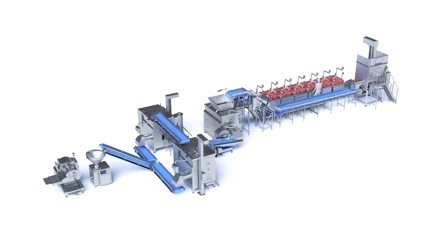

Your full line supplier

We can support you beyond the poultry meat preparation process and have all the equipment for a fully integrated line to create minced poultry portions for retail or QSR purposes. Our state of the art further processing equipment including solutions to portion blocks of minced poultry meat before packing and labeling for final dispatch.