Information

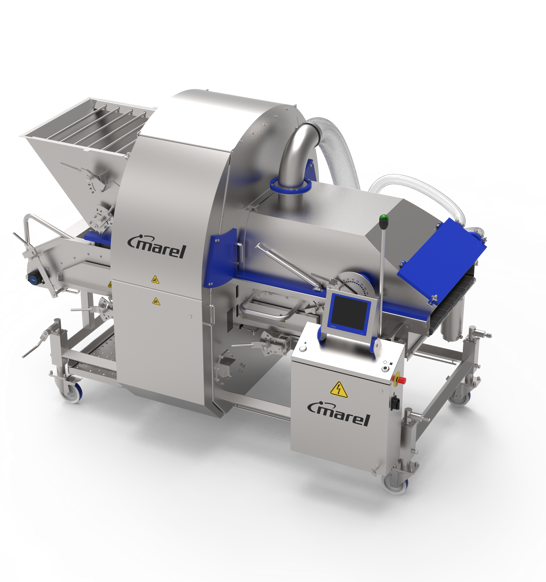

The RevoCrumb leads the way in advanced crumb coating solutions for products like schnitzels and tenders. Its unique technology and proven results truly distinguish it in the market.

Superior control of fine and coarse crumb distribution

What sets the RevoCrumb apart is its patented crumb management system, which separates fine and coarse crumbs and then lets you direct their flow onto the product. While some other machines can divide the crumbs, only the RevoCrumb allows you to adjust the individual flows of fine and coarse crumbs for the top and bottom bed . This results in exceptional product appearance and quality.

Lowest levels of crumb breakdown

In contrast to conventional machines that rely on auger screws to transport crumbs, the RevoCrumb uses a wheel that gently scoops crumbs and moves them to the top of the machine . This unique feature places significantly less stress on the crumbs and minimizes breakdown in a manner unachievable by screw systems. Thus, the RevoCrumb enhances the appearance of your products and minimizes crumb wastage more effectively than any other coating equipment on the market.

Belt marks eliminated

With RevoCrumb’s adjustable pressure rollers and vibrating plates, you can significantly increase crumb adhesion and pickup to maximize your yield. Seamlessly following our Active Batter Applicator , which delivers product to the RevoCrumb perfectly coated in batter, these solutions work in tandem to eliminate belt marks in the coating on the underside of products, ensuring flawless presentation every time.

Features:

- Handles coarse and fragile crumbs such as J-crumbs, panko and cornflakes

- High line speeds, up to 25 m per minute

- Available in 600, 700 and 1,000 mm belt widths

- Connects to cyclone vacuum for dust-critical applications

- Hygienic design for quick and easy cleaning