Information

Unrivaled detection capabilities

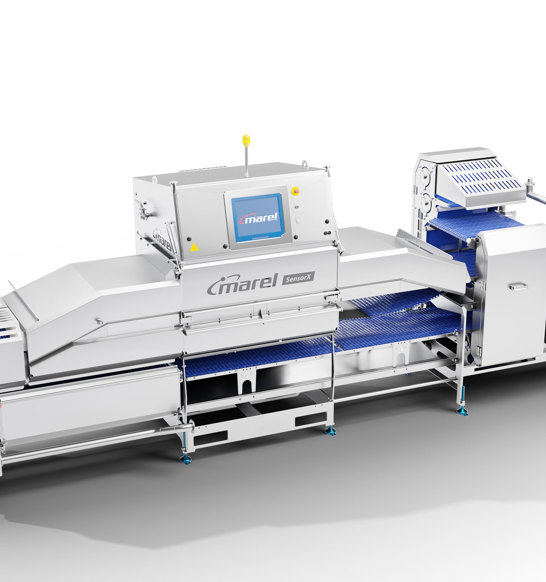

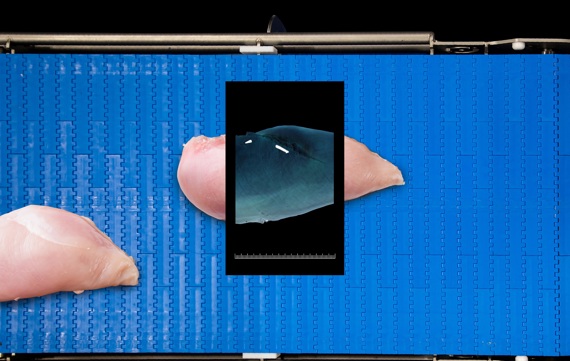

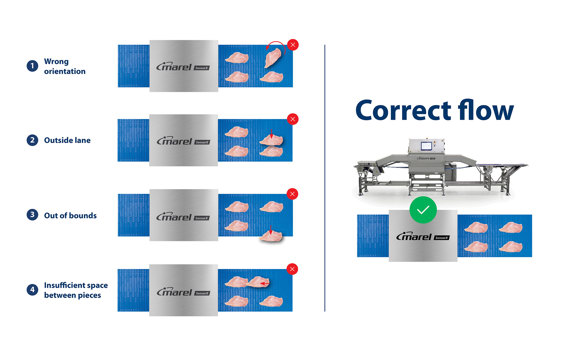

SensorX’s industry-leading X-ray technology detects bone and other hard contaminants, such as metal, stone and glass, with unprecedented accuracy and reliability. This not only increases the quality of the product but also minimizes the risk of recalls and customer complaints.

Less rework and less labor

SensorX has a false-positive rate of less then 3%—the lowest in the industry. The system can also detect bone fragments down to 2 mm with 99% reliability, which is more accurate than any other system available. This means less over-trimming, less rework and product handling, fewer operators and improved product quality.

Protect and enhance your brand

SensorX is your guarantee to customers and consumers that they will always get safe, high-quality products from your brand. For many years SensorX has set the poultry industry standard for bone detection. The system has built a reputation amongst global food processors as the most accurate, consistent and reliable way to detect and reject bone.