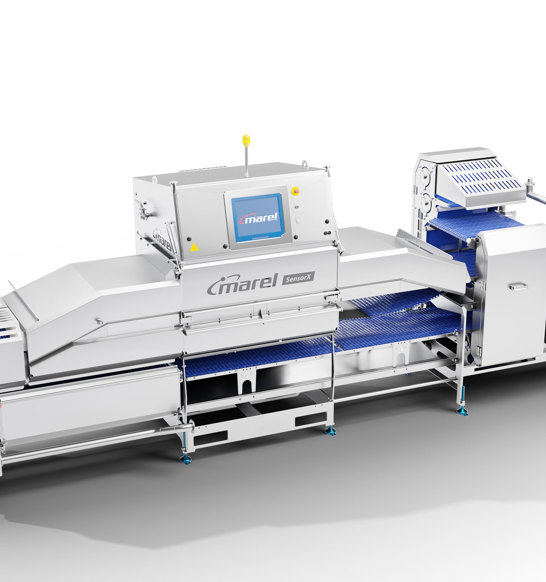

Information

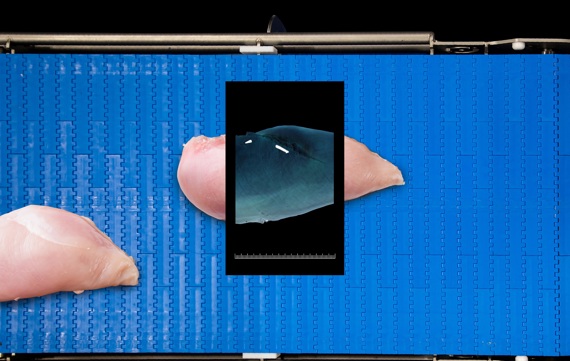

Unrivaled detection capabilities

The SensorX advanced bone detection capabilities ensures unprecedented results when compared to other automatic bone detection systems. Using cutting-edge X-ray technology, the SensorX has also been designed to detect other contaminants such as metal, stone and glass.

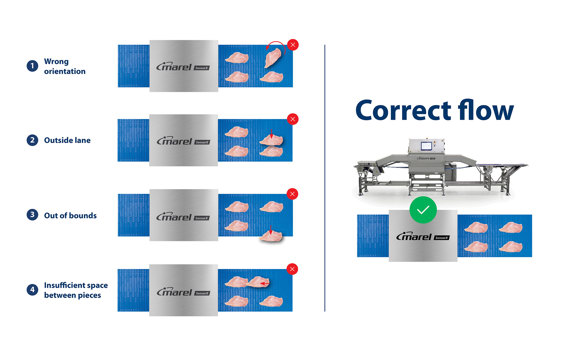

Less rework and less labor

SensorX’s software not only reduces the occurrence of false positives, but also detects difficult to find bone fragments more accurately. This means less rework, fewer operators and improved product quality, further showcasing the machine’s performance and reliability.

Real-time monitoring with Marel Software

Marel Software enables food processors to monitor SensorX operations in real time, while also utilizing historical data on bone rate. The plant manager is able to monitor actual performance of the machine, while the program can deliver reports on throughput, infeed quality and bone detection. This allows processors to quickly improve processing performance.