Information

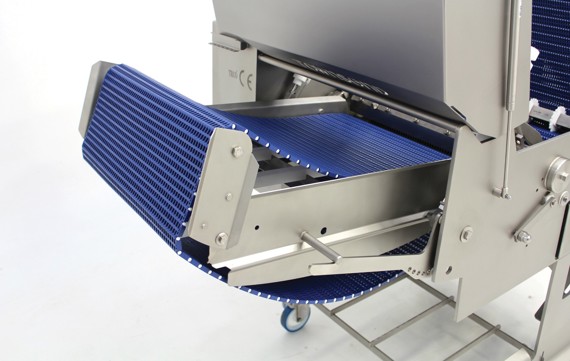

The derinding skinner Townsend SK 15-340 is a conveyorized skinner that is used for removal of pork skin in applications such as bellies, jowls, back fat, plates and other pork trimmings. This versatile skinner can also be used in flatter heavy beef applications where heavy fat needs to be removed as well.

Features

- Available in three skinning widths

- Line bored cabinet creates a perfect alignment between tooth roll and skinning mechanism.

- Shoe can remain on the machine during sanitation to prevent damage

- Single drive belt located on one side for easier maintenance

- Adjustable height exit conveyor is ideal for a multitude of production line layouts

- Available in adjustable and fixed lower base

- Hood assist to aid in opening and closing of the hood

- Available in adjustable and fix-blade clamp options

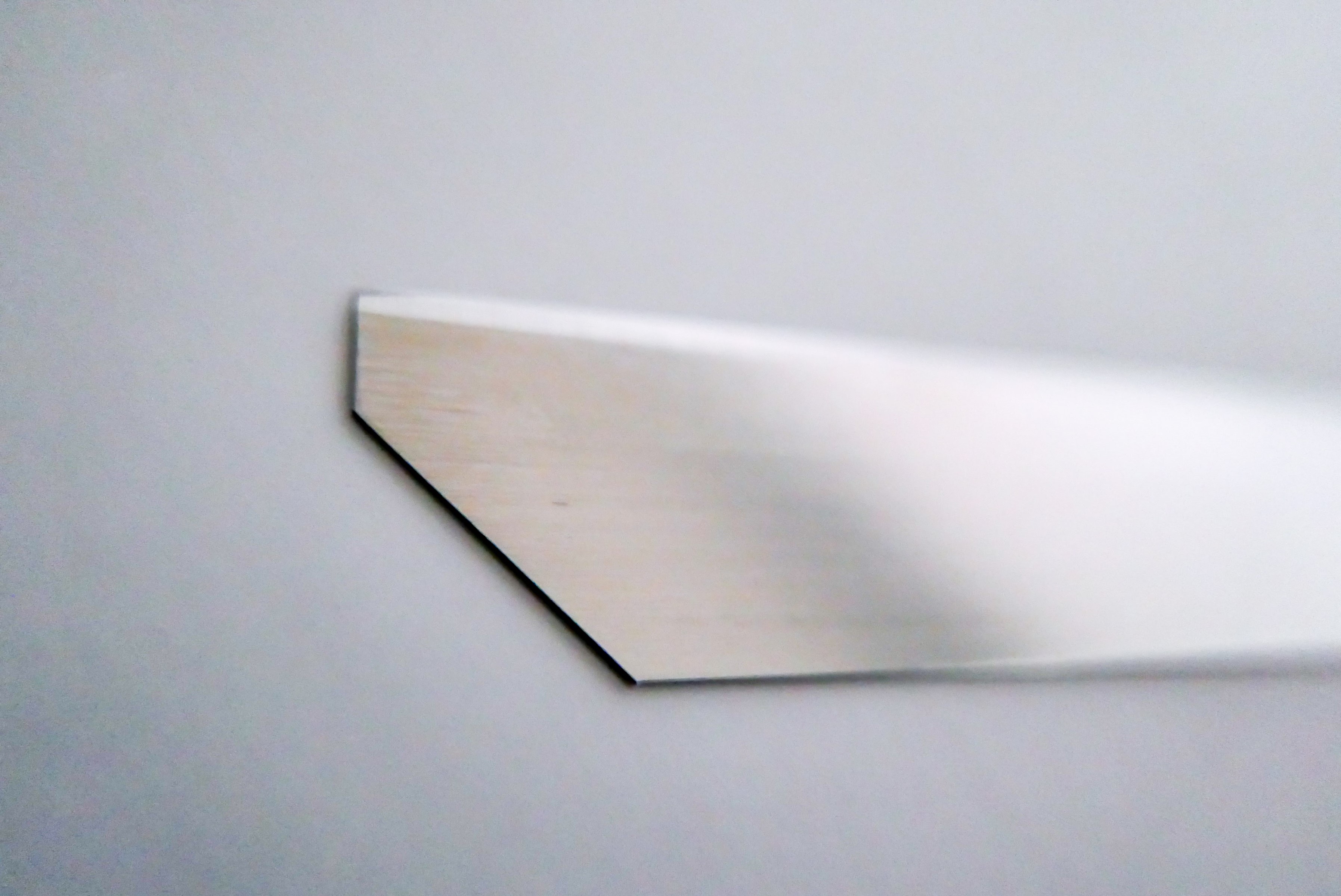

- ThinAdjust control allows for skinning thickness to be adjusted while the machine is running.

- Available with infeed and exit extensions to allow for a multitude of production line layouts

- Open conveyor frames for easy maintenance and sanitation

- Low cost of ownership

- Easy to adjust air or spring top feed cylinders allows for optimal performance on many different products.

- Easy to lock-down top feed mechanisms

- Available in fixed or open bite configurations

- Easy to adjust air or spring open bite cylinders allows for optimal performance on many different products