Information

The SmartWeigher inline overhead whole product weighing system is very versatile and can be applied at multiple locations in the processing plant. In the distribution (selection) line, SmartWeigher directly follows the chilling tunnel.

Match products to orders

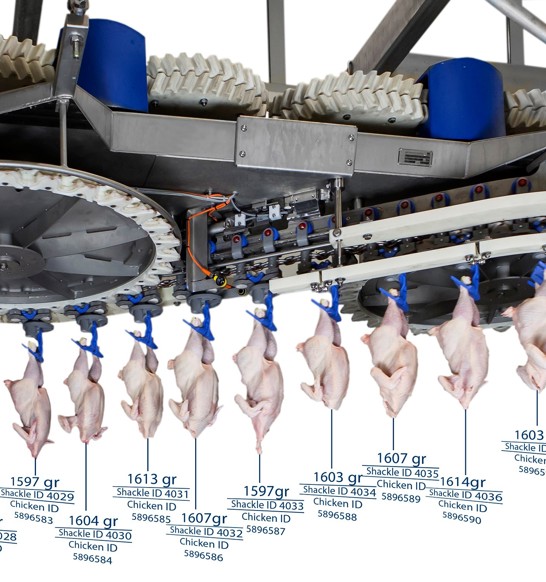

At this location in the plant, SmartWeigher GDR weighs whole chilled products, after which the optimum destination of each product is determined by Innova PDS. The ability to match products effectively to customer orders and get the most out of each product and product part is crucial for the “bottom line” of any processing operation. Thanks to SmartWeigher, wrongly allocated products belong to the past.

SmartWeigher is capable of handling the highest speeds, with utmost precision and robustness. Its inline weighing performance, separating light, average and heavy birds, enables fast decision-making about the final destination of product and product parts in scope at that moment. The system knows accurately how to control the product flow into the cut-up lines.

Grading and distribution line

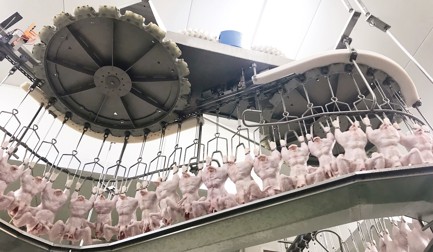

In the distribution area, SmartWeigher can be part of a larger integrated solution, the SmartWeigher Grading and Distribution Line. It consists of a SmartWeigher, IRIS vision system, a specifically developed turning shackle (that positions products optimally for the SmartWeigher and prevents wings from touching) and unloading stations. All of this is controlled by Innova PDS software.

The award-winning SmartWeigher Grading and Distribution Line with an 8” pitch enables accurate weighing, grading and distribution of broilers at the highest possible processing speeds. The result is that every single product in the line is put in its most profitable form.

- Can be installed at multiple locations in the plant

- Precise inline weighing and robustness at highest speeds

- Product weighing directly after chilling tunnel in distribution line

- Match products effectively to customer orders

- Get the most out of each product and product part

- Integrated solution in the Distribution and Grading Line

- Fully integrated into Innova PDS plant-wide information and control system

- Weigh sensor calibration needed only once during assembly

- Turning shackles prevent contact between products

- User-friendly components with low maintenance requirements

- Simple hygienic design

- Low cost of ownership