Information

Increase carcass weight yield

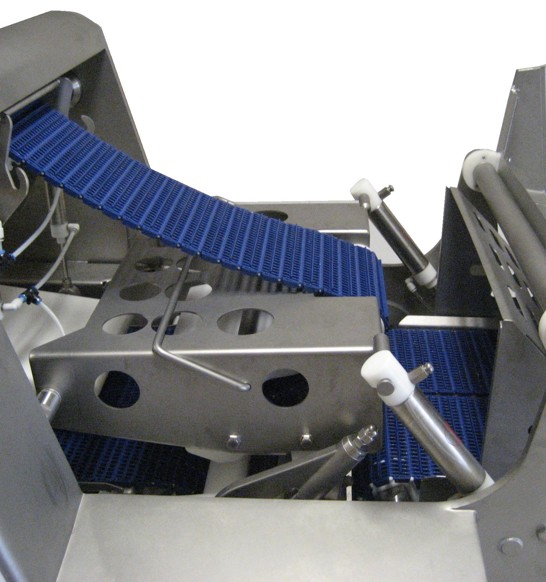

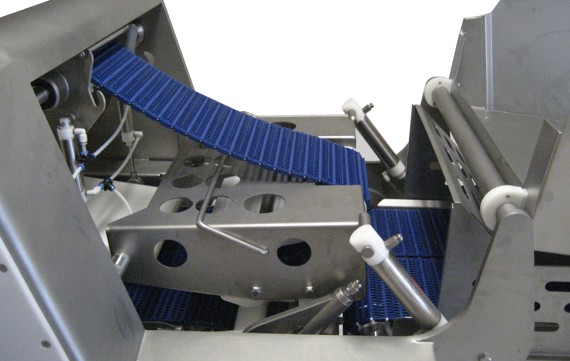

The Townsend AT 21-620 comes from a long line of successful pork butt trimmers. Improved technology and enhanced features allow the AT 21-620 to provide processors with improved yields, higher accuracy and reliability, increased throughput and a machine that is simple to operate.

Simple operation

The machine’s design allows for easy operation, maintenance and cleaning.

Features

- Available in right- and left-hand configurations

- Market-leading accuracy and throughputs

- Improved yields of 0.1% back to carcass weight

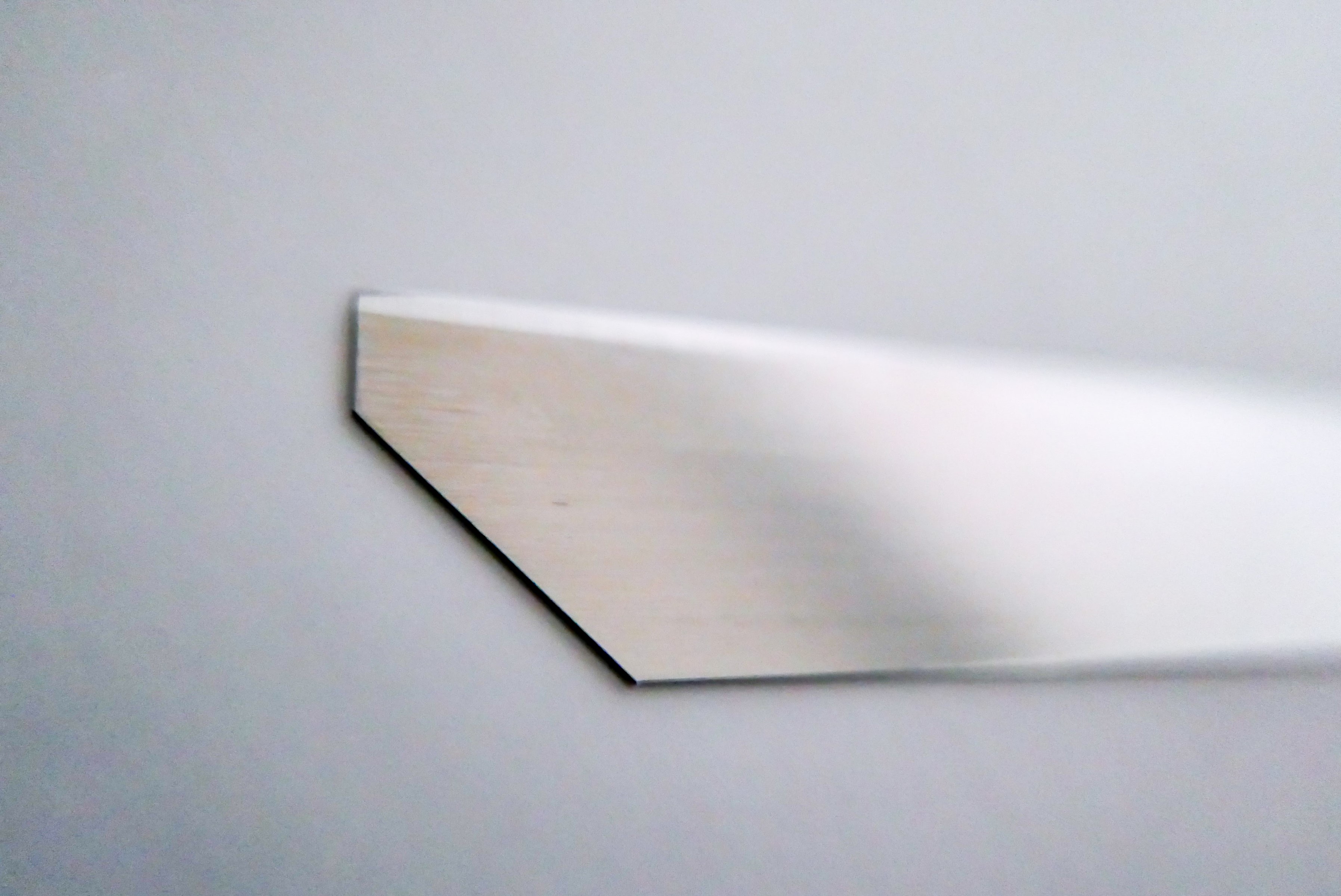

- "Line bored" cabinet creates a perfect alignment between tooth roll and skinning mechanism

- Shoe remains on the machine during sanitation to prevent damage

- Drive belts located on one side for easier maintenance

- Adjustable height exit conveyor is ideal for a multitude of production line layouts

- Open design for easy maintenance and sanitation

- Low cost of ownership

- Easy to lock down top feed mechanisms

- Unique machine designed for specific processing of pork butts

- Easy to operate touch-screen for adjustments for high-quality end products

- Heavy gauge structure resists damage and requires less maintenance

- Sealed cabinet improves sanitation, protects parts, requires less maintenance with less cleanup cost

- Keyed side panels provide easy and quick access to electrical and mechanical components, reducing downtime

- Swivel casters make it easy to move around for cleanup and maintenance

- Interlock belting for longer life-span, improved sanitation, and easy repair or replacement

- Delrin rail supports improve sanitation and makes for smooth operation

- Machine disassembles quickly for easy cleaning and maintenance

- Built-in storage for all removable parts

- Interlocked hood and guards prevent access to moving parts

- Optional abscess wash-down system