Information

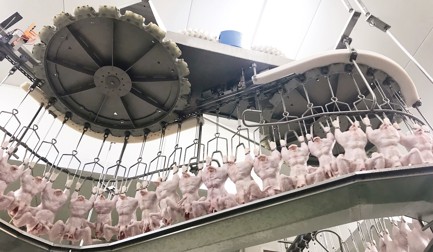

The section taking product out of the eviscerating shackle is driven by the eviscerating line; the section transferring products to the chilling shackle is driven by the chilling line. A unique feature is that the speed of both lines can vary.

Products are transferred from the unloading section (eviscerating line) to the hanging section (chilling line) in loose trolleys which run in an intermediate transport system.

By installing a weighing unit (TR-EC/GI) in the flexible intermediate transport system, it is possible to weigh individual products before they go for chilling. This gives early warning of the weight range of a flock and allows plant management to monitor any weight loss during chilling.

- Left or right turning execution

- Synchronization between lines not required

- Less chance of broken legs

- Live weight of 800 - 3500 g

- Individual products weighed

- Improved balancing of interplay of forces