Minimized loading risks

Although automatic catching machines have been on the market for a number of years, 95% of broilers are still caught manually around the world. To avoid damage to broilers, catching must be made as easy as possible. This also means paying close attention to the design of the modules into which birds, once caught, will be loaded.

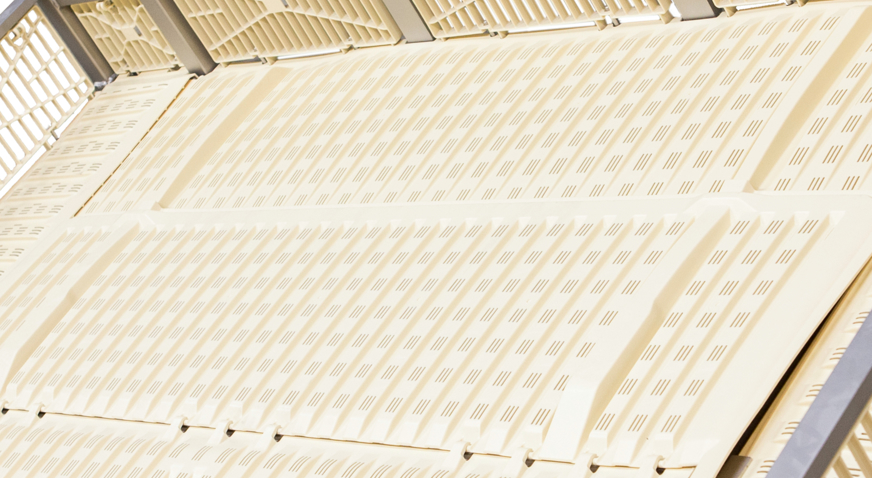

Although plastic crates are still used, operators mostly prefer multi-tier containers or modules. These modules should be brought into the growing shed and placed as close as possible to where catching is actually happening; catchers should not have to walk any distance with birds. It is particularly important that the module design allows modules to be placed close to walls or corners, so that those last few birds can be caught and loaded. Extractable trays are therefore not preferred, they take up too much space. Modules should also allow birds to be loaded easily with minimal risk of damage. Loading openings should be big enough to allow birds to be loaded downwards onto their feet. Marel’s ATLAS transport modules open up to give a wide loading opening.

The truck journey

Loading a truck will typically take up to an hour. The journey to the processing plant should be as short as possible. Ideally, broilers should not be in their transport modules for more than a few hours. On the truck, measures will have to be taken to protect them from extremes of heat and cold and from inclement weather. Transport module design should allow for efficient ventilation, both when the truck is parked and when it is in motion. Particularly important is floor design, allowing birds to grip when the truck brakes, takes turns or drives a bumpy road.