Overhead conveyor drive systems are perhaps the most critical of critical control points in a high throughput multi-shift poultry processing plant. Failure of any one overhead conveyor system will always result in lost production.

The ability to drive long air chill lines with 100% reliability was the main driver behind development of the Marel Active Tension Control (ATC) system some years ago. Today, this technology is more relevant than ever.

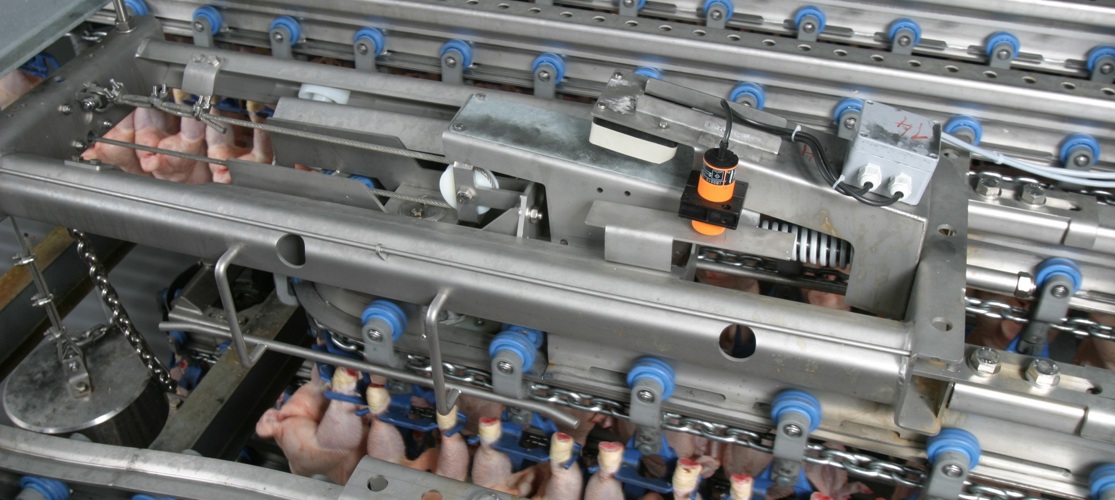

Measuring chain tension

The ATC system divides each processing line into smaller sections, each with its own frequency-controlled drive and device for measuring chain tension. A master drive unit determines line speed and a master tensioner the level of tension in the chain. The system’s software continuously monitors chain tension in each section, using feedback information from the measuring device to ensure uniform tension throughout the whole processing line. What if a measuring device detects that tension in a particular section deviates from the level set at the master tensioner? In that case, the software fine-tunes the speed of the section’s frequency-controlled drive to bring tension in the section back to the pre-set level.