Chicken feet are considered a cheap, nutritious food option and a protein-rich snack

Chicken feet, while not completely unknown in Europe, are largely an African and Far Eastern product when it comes to human consumption. In those parts of the world, they are a delicacy, whether served as a snack or the meat ingredient of a meal. What was once a low-value by-product has become a profitable export item for poultry processors worldwide.

Chicken feet are no longer just used for pet food. Their value has been upgraded and they have become a high-value export product for human consumption. What is more, the upgrading of feet benefits sustainable carcass balance too, Once the horny outer skin has been removed, chicken feet are largely tendons and skin with no muscle. They have a gelatinous mouth feel.

Chicken feet are no longer just meant for pet food purposes. Their value has been upgraded and they have become a high-value export product for human consumption. As for carcass balance, the better utilization of feet also adds to more sustainable processing of the entire chicken. Without their horny outer skin, chicken feet are largely tendons and skin with no muscle. They have a gelatinous mouth feel.

Around the world, feet are exported mainly to China, Africa, Hong Kong, and Vietnam, where they are considered a delicacy. In South Africa, they are part of the popular Walkie Talkie (chicken head and feet). They can be grilled, boiled, or fried, and seasoned with pepper, curried, served with porridge, or added to stews or soups. Often, they are sold as street food at markets, bars or food stalls. Chicken feet are considered a cheap, nutritious food option and a protein-rich snack.

Chicken feet are considered a cheap, nutritious food option and a protein-rich snack

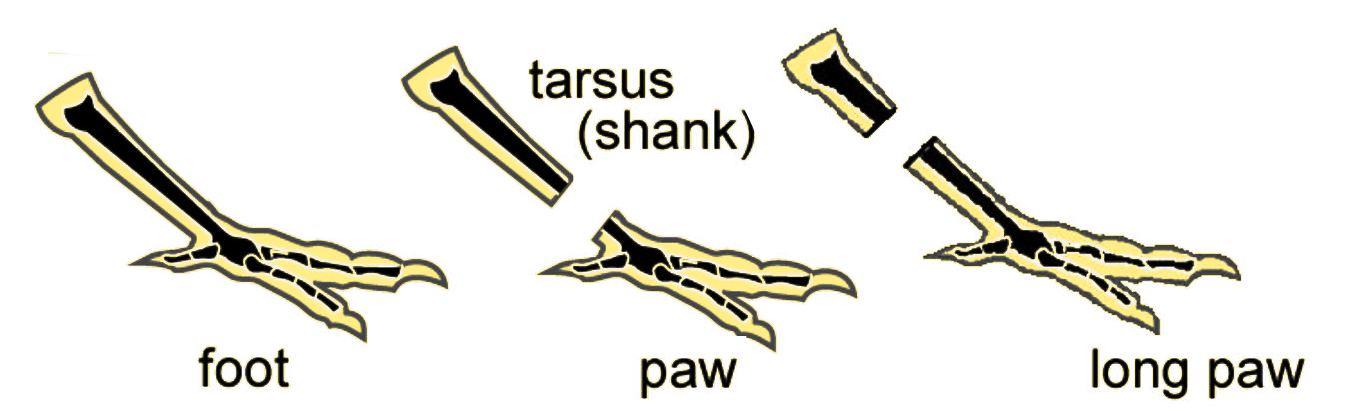

JBT Marel can offer a complete system for processing either chicken feet (including shanks) or paws (feet without the shank). The system comprises a feet cutter, a foot scalder, skinner and chiller. Optional extras are a foot unloader for unshackling feet condemned by the vets, a paw cutter, which separates the foot from the shank, and special defeathering shackles, which allow feet to sit more deeply in the shackle. The system is good for up to 15,000 birds per hour.

Feet are cut off either in a dedicated leg cutter or in the transfer unit (LineLink DE or TR-DE) to the evisceration line. In low volume plants where evisceration is largely manual, the foot cutter is installed at the end of a combined plucking and evisceration line. In earlier days, given that feet normally went to waste in a US or European plant, it seemed logical to keep foot removal in the plucking area, together with feather removal. Today, there is no longer any reason to do this.

It is often the case that only feet from broilers which pass the veterinary check in the evisceration line can be used for human consumption. For this, JBT Marel also has the solution, which is a 20-unit Selective Foot Unloader. The evisceration and plucking lines are linked by intelligent software such that such that if the vet condemns a bird, the feet from this bird alone are unshackled in an automatic unloader. Unwanted feet therefore do not reach the foot processing system.

In addition, it is possible to reject feet based on the detection of foot lesions. The Selective Foot Unloader then removes that foot and that foot only from the shackle. Unwanted feet therefore do not reach the Feet Processing System.

In the Far East, there is a market for paws. One advantage for having a paw cutter in the line is the upgrade of broken feet possible with this machine. Usually, broken feet have a low value and are taken out of the process. A Paw Cutter, however, can separate the actual foot from its shank just below the bottom of the shackle. This cut is anatomic. In a processing plant, the Paw Cutter is installed after the Selective Foot Unloader. Feet and shanks are then unloaded separately as valuable products.

JBT Marel’s complete Feet Processing System works as follows. Feet or paws are forwarded into a double-walled Feet Scalder, which is completely closed to prevent heat loss. Horny skin on the foot is softened, allowing it to be removed later on. A screw conveyor moves feet/paws through the scalding system, which is filled with water at 60°C [140 °F]. After that, the Feet Skinner removes the horny skin and the nails using rotating rubber fingers. Horny skin is discharged from the skinning system via a central drain.

From the skinning system, feet/paws move to the Feet Chiller, a screw chiller where they are cooled in agitated water. The system comes complete with a blower for agitating the chilling medium. After the chilling process, feet/paws are ready for packing and for the journey to the consumer.

Thanks to JBT Marel’s complete, high-capacity system for the efficient processing of feet and paws, poultry processors can turn broiler feet and paws from low-value by-products into profitable export items. Improving carcass balance and preventing waste in this way is an eminently sustainable approach. Options such as selective unloading and paw cutting help processors streamline their operation even more, truly optimizing product value. The Feet Processing System gives poultry processors a significant opportunity for acting sustainably, while increasing their export potential and improving profitability at the same time.

News

Our dedicated team is here to help and answer any questions you may have. Please complete the form, and we’ll get back to you as soon as possible. We look forward to hearing from you.