NuTech in 1993 could handle 8,000 bph. Its Nuova cousin can process almost double!

In 1971, just over fifty years ago, Stork PMT launched its very first P40/48 automatic eviscerator, beginning the mechanization of a key part of the primary process. In the decades to follow, Stork/Marel continued to pave the way for novelties and innovations, revolutionizing the art of evisceration. Today, Marel is still the frontrunner in this field.

In those early days, Stork development engineers had to overcome the conservatism of an industry where evisceration had always been done manually. They had to focus on all aspects of the process, doing the job well, hygienically and with no loss of yield or quality.

Right from the start, Stork engineers were keen to develop an eviscerator as opposed to a drawing machine. An eviscerator loosens the crop, allowing its removal along with the viscera pack, whereas a drawing machine does not do this. There were two main reasons for this approach. Breaking the connection between the crop and the rest of the pack risks contaminating the carcass and neck flap with crop contents. If the connection is not broken, the drawn pack can then fall back into the abdominal cavity.

Major equipment manufacturers were still offering drawing machines in the 1990s. Drawing machines have since disappeared.

NuTech in 1993 could handle 8,000 bph. Its Nuova cousin can process almost double!

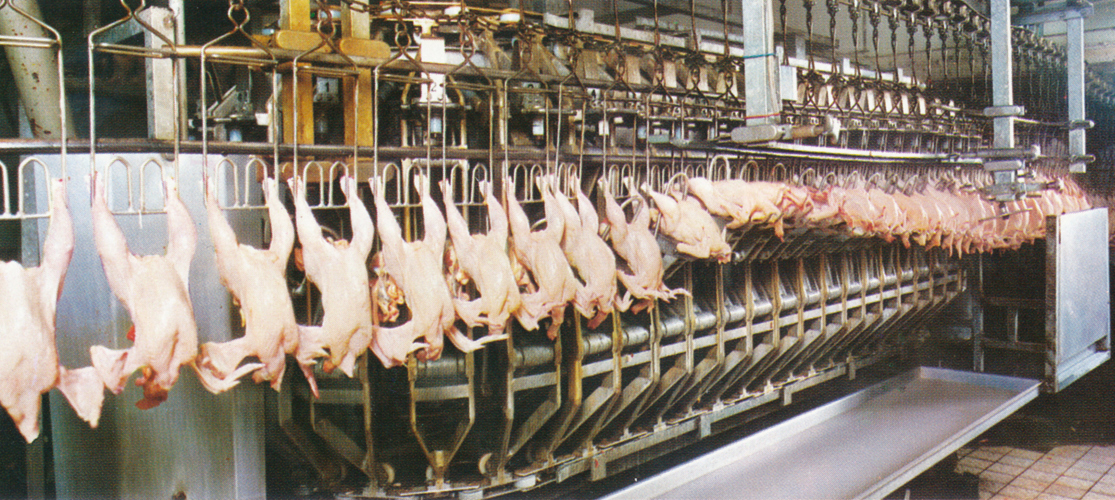

Stork PMT chose a straight shackle for its automatic evisceration system as opposed to a shackle with a folded foot. In a straight shackle, the carcass hangs obliquely, whereas it hangs vertically from a folded foot shackle. With a straight evisceration shackle, there is therefore less risk that automatically drawn packs will touch and contaminate the back of the carcass.

An automatic eviscerator is the heart of any evisceration system. The operations in front of it, vent drilling and carcass opening, prepare the carcass for evisceration. Those behind it, except neck cracking and removal, largely clean and tidy up the carcass and its neck flap for the next stage in the process.

The 1970s and early 1980s saw Stork introduce two generations of automatic eviscerators, each a radically new design and each improving on the performance of its predecessor with fewer units required for the same hourly capacity. Round carrousels replaced the oval configuration of the original P40/48 and have remained the industry standard ever since. Speeds of the fastest automated lines in the seventies were typically 4,000 bph; in the early and mid eighties this rose to 6,000 bph. The end of the eighties saw the first 8,000 bph lines, once again a Stork first.

Stork PMT was the first and only equipment supplier to offer a combined venting and opening machine. the logic being that once a carcass was correctly positioned for the two operations why not do this in a single machine? The VOC carrousel system was a trailblazer in other ways too. Instead of opening the carcass by cutting straight across and risking damage to the underlying vent and intestine, the opening blade followed the contour of the pelvic bone. Although Marel now offers separate venting and opening machines for the highest hourly capacities, the combined VOC concept is still suitable for lower line speeds.

With the launch of the Stork NuTech evisceration and giblet harvesting system, 1993 saw a truly groundbreaking event in the history of automatic evisceration.

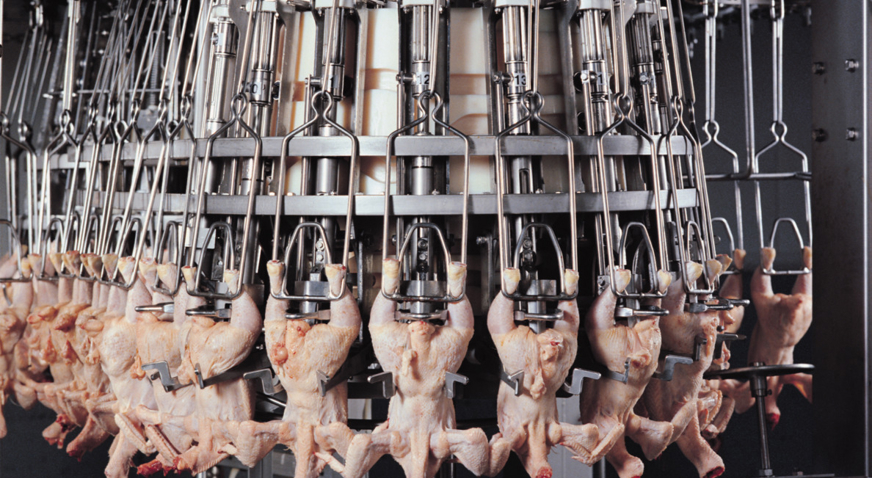

NuTech’s main evisceration departure was the complete separation of the viscera pack from the carcass and its automatic rehang to a separate giblet harvesting line. For veterinary inspection, carcass and giblet harvesting lines had to be synchronized in such a way that carcasses and the packs taken from them were always presented together to the veterinarian. Rejection of a pack would mean rejection of its carcass.

The transfer of each pack to its own shackle opened the way for harvesting all edible giblets automatically. Even where giblets were still being harvested manually, the new method brought considerable advantages.

Giving each viscera pack its own shackle upgraded the image of giblets as products in their own right and not just by-products. The flexibility of harvesting giblets from a shackle suspended from an overhead conveyor system meant that this operation could now be done in an adjoining room and at a height convenient for operatives. By color-coding pack shackles, individual operative performance could now be monitored, resulting in a substantial increase in giblet yields. There was a hygiene benefit too. Viscera packs were transferred to their shackles with intestines hanging down and away from the edible giblets.

Virtually right from its launch, fully automatic giblet harvesting was a NuTech option. Whereas manual giblet harvesting was often the first to suffer when processing plants were short of labor, this process was now no longer reliant on people. Not only did NuTech save a lot of labor, fully automatic giblet harvesting meant that giblet yields could leap too.

They say that imitation is the sincerest form of flattery. All equipment suppliers now offer systems based on the automatic transfer of giblet packs to a separate pack shackle pioneered by Stork.

Some ten years after NuTech was launched, Stork PMT came with its all-new Nuova concept. The unit’s central cam was conical rather than cylindrical, allowing the easier accommodation of heavier carcass weights. As of now, carcasses went round the machine with their backs rather than their breasts to the cam. Nuova also boasted a simpler drawing spoon and fewer units for a given hourly throughput. The positioning of viscera packs in the pack shackle was more positive resulting in changes to automatic heart and liver harvesting. These have lifted giblet yields still further.

Nuova has more than proved itself in processing plants all over the globe. Since its launch, the concept has been continually updated and refined.

In all areas of the processing plant, software for machines, systems and processes is becoming more and more important. That also goes for the evisceration department. It is, therefore, not surprising that the latest 2022 version of the Nuova machine will make the transformation from a purely mechanical operation to a data-driven, intelligent process. Digitalization will replace handwheels and manual levers. Control of the machine will enter the digital era too. Instead of buttons and knobs, a user-friendly touchscreen will give access to machine settings and even machine health analyses. When connected, the eviscerator can even be monitored remotely.

It will be possible, for example, to adjust the machine settings to flock variations. A single tap on the touchscreen is all that is needed to set the machine precisely for an upcoming heavy flock.

Marel has come along way in the fifty years since Stork PMT launched its first eviscerator. The latest evisceration systems can handle 15,000 broilers per hour, producing truly top carcass and giblet yields and quality. The systems are ultra-reliable, performing virtually around the clock in many plants. An example of how far Marel has come since the introduction of NuTech in 1993 is that the 24-unit NuTech eviscerator could then handle 8,000 bph. Its Nuova cousin can process almost double!

News

Our dedicated team is here to help and answer any questions you may have. Please complete the form, and we’ll get back to you as soon as possible. We look forward to hearing from you.