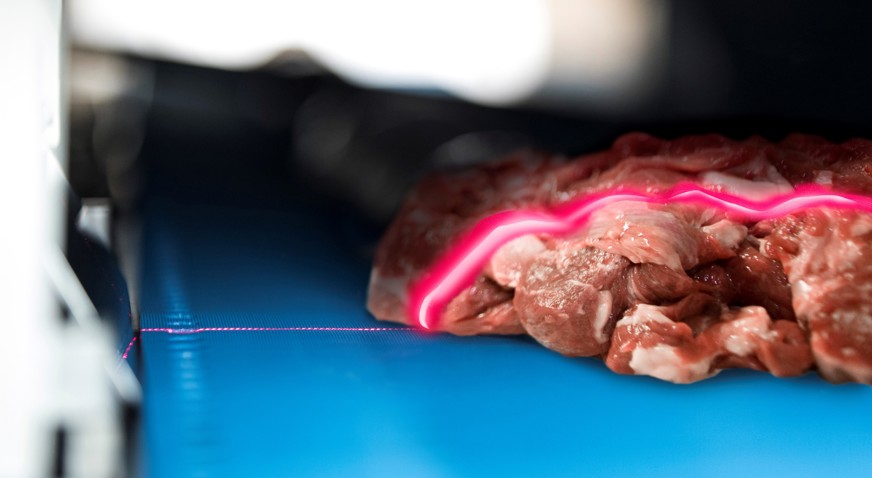

Increasing demands call for higher standards in trim inspection

With market trends including more health-conscious consumers, pricing pressure from supermarkets, increasing litigation and stricter regulatory standards, there’s almost no scope for error when it comes to fat analysis and detection of hard contaminants.

Fragments of bone, metal, and glass can cause injuries and illness, and inaccurate chemical lean (CL) values can lead to costly complaints. Facing the severe risks of harm to consumers, product recalls, litigation, fat claims, loss of customers and reputational damage, many processors are seeking more effective methods of trim inspection.

Fortunately, advancements in trim inspection technology offer great opportunities to improve safety and CL accuracy while also streamlining production and reducing giveaway.

This article outlines how X-ray inspection helps you to overcome these challenges and earn an outstanding reputation for quality that will give your company a competitive edge.

Virtually eliminate product recalls

Product recalls are an essential measure to protect consumer safety in the event of food contamination. However, once the risk to consumers has been eliminated, processors are left facing severe consequences for their brand.

The costs of a recall are enormous, both in terms of direct financial impact and harder-to-quantify reputational damage. This is especially true in today’s era of social media, where negative consumer experiences can spread across the globe in a matter of minutes.

The good news? Modern X-ray inspection technology is making it easier than ever to prevent contamination due to bone, glass and metal. X-ray technology is far more effective than traditional methods and is overtaking manual inspection as the global industry standard.

X-ray inspection makes it possible to offer outstanding levels of consistency, accuracy and safety, giving you the peace of mind that your products meet the most stringent quality standards.