Why benchmark suppliers?

1. Ensure you get what you pay for

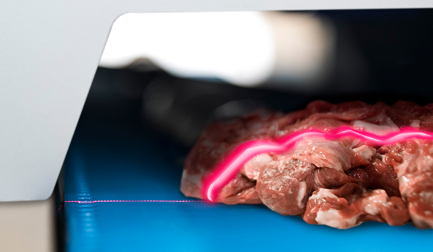

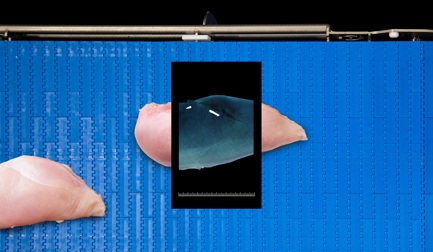

CL accuracy and the presence of hard contaminants in trim can vary greatly between suppliers. Analyzing and collecting data about the incoming raw material gives a clear overview of the exact number of contaminants in each batch received, as well as precise CL levels. These insights allow processors to verify that suppliers are delivering as promised and that they are actually getting the raw materials they paid for. And importantly, it gives the opportunity to claim for any materials that do not meet specifications.

2. Increase your negotiating power

Knowing the exact number of hard contaminants in each batch of incoming raw material, and having accurate CL measurements, allows processors to make strategic, data-driven purchasing decisions. By understanding how suppliers stack up, an organization can develop strategies to ensure they get the best possible value for money. It also provides the leverage to negotiate better pricing or prioritize reliable suppliers that consistently provide on-spec raw material.

3. Maximize processing efficiency

By collecting data and connecting valuable metrics to each supplier, over time, processors are able to divert their business to suppliers where they can be confident that raw materials will consistently meet their specifications. This is an important factor for maintaining processing efficiency. Quality raw materials minimize the need for corrective actions during the production process, such as unexpected contaminant removal and rework. It also reduces the need to interrupt the production flow to adjust CL.