By highlighting animal well-being in the sustainability scorecard Marel is ensuring environmental and economic responsibility in the most crucial stages of the lifecycle of the product. By instituting good animal well-being practices in general, we can support food processors in increasing the quality of products and production while simultaneously reducing the carbon footprint using Marel solutions.

Sustainability themes drive automation

Marel addresses current and future trends in the poultry industry

Sustainability themes such as carbon footprint, carcass balance, animal well-being and food safety are stimulating new automated technologies in the poultry industry. Fully aware of this advancing automation trend, Marel continues to focus heavily on developing innovative poultry processing solutions.

Animal well-being

Animal well-being is a hot issue for consumers in the European food market. More and more, a shift can be seen towards slower growing chicken breeds in the farms and related products on the shelves. The use of antibiotics is being reduced progressively. Up to their last moments, chicken should be treated humanely, while the most respectful way of anesthetization should be applied.

Particularly in our live bird handling and stunning systems, Marel Poultry maximally takes into account animal well-being. Once they are loaded in the ATLAS (Advanced Technology for Live bird Arrival System) SmartStack transport modules on the farm, birds remain untouched by human hands all the way and they’re not subjected to abrupt movements.

Broilers, therefore, avoid the major stress factors which other systems subject them to. They stay peacefully in their trays during truck transport, lairage and destacking until they are gradually sedated by the CAS SmoothFlow system. Only after anesthetization they are taken out of their trays to be shackled to the processing line.

Carbon footprint

Reducing the CO2 footprint has become one of the goals of our research and development team. New technologies are designed while taking into consideration less use of water and energy. In addition, Marel’s portfolio comprises also wastewater treatment, a truly important environmental aspect.

Another example of carbon footprint reduction is ATLAS’ SmartStack transport module. Its ingenious construction features a bottom tray which doubles as a pallet. This enables transportation of more birds per module, while they enjoy the most headroom in the industry! This means fewer truck movements from farm to processing plant, implying a reduction of the carbon footprint.

Traceability

More and more, consumers worldwide want to know about the origin of their food. They want to be sure that the entire production process has been in trusted hands, guaranteeing absolute food safety. As for poultry meat, consumers want to buy chickens of which the entire timeline is known, from farm to fork.

Marel’s poultry innovations enable the traceability capacities that are required by our customers. Particularly AXIN software plays a major role in acquiring and controlling all product data, needed to be able to trace a certain product in the process flow. In case of an unexpected recall situation, Innova allows for precise identification of an inferior flock on the plant’s product input side or withdrawal of a specific product lot from the supermarket shelves.

Carcass balance

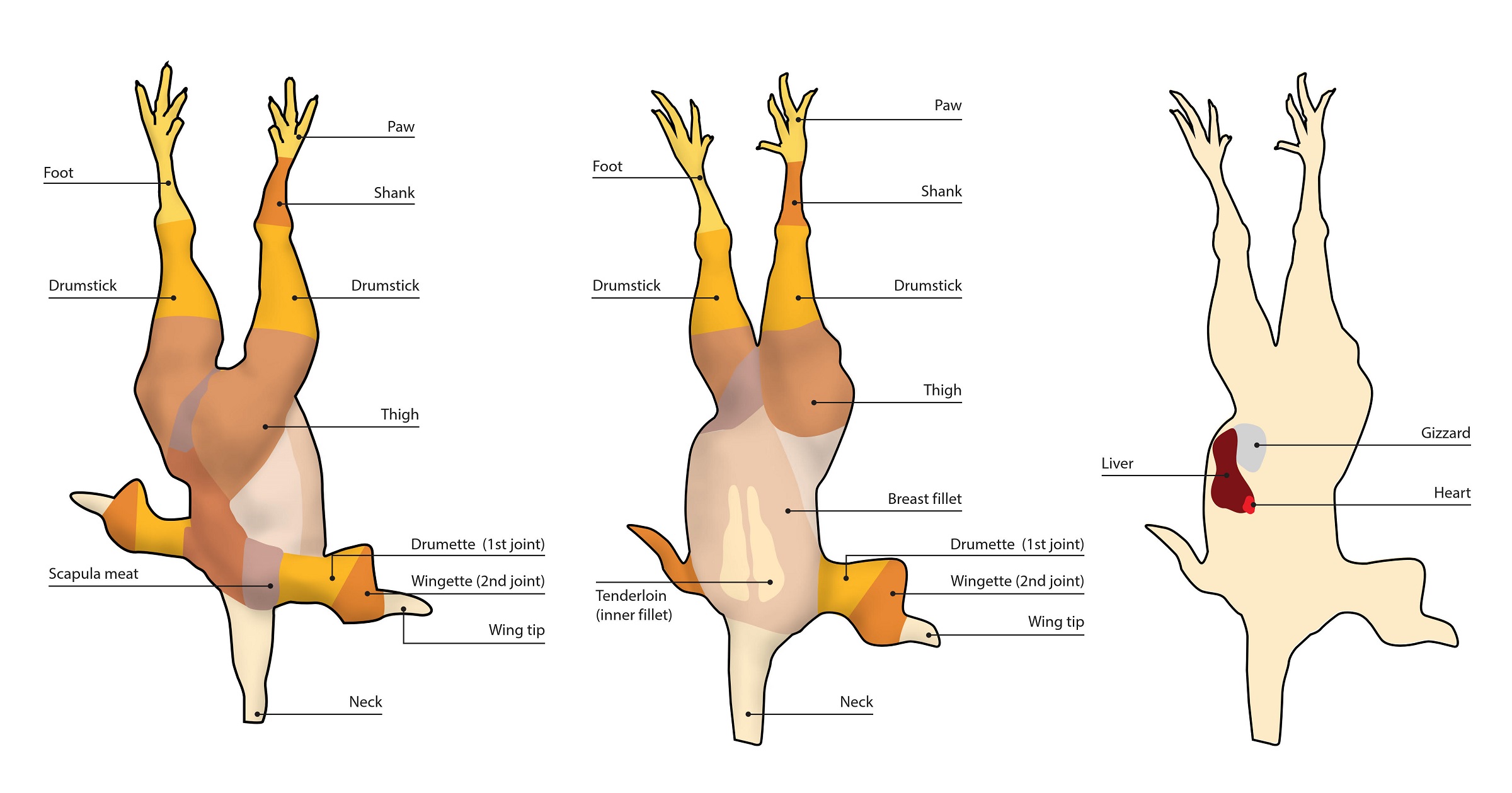

Improved utilization of raw materials has become increasingly important as the world population grows and demand for protein increases. Around the planet the awareness of carcass balance in the poultry industry—in other words maximizing the value of every part of the chicken—is growing. For more and more people using just the breast meat of carefully reared chicken and underrating the rest, perfectly edible food rich in proteins, is not making sense.

Given the increasing attention being paid to sustainable production and a growing world population to be fed, it is entirely logical to add as much value as possible to each and every part of the chicken, especially to such a tasty part as the leg.

And when we're talking about full carcass balance, the edible giblets of a broiler certainly should not be overlooked. Once again, automation drives sustainability here: the process of extracting giblets from the carcass, separating them, preparing them, and turning them into appealing food involves many systems that have replaced tasks previously performed by humans. Marel provides poultry processors with equipment and software that enable them to maximize the utilization of every part of the broiler.

Deboning and portioning

By automating manual deboning and portioning operations, poultry processors can align with the carcass balance trend and, at the same time, increase their cost-effectiveness, because deboned meat has more value than bone-in meat. Automation allows for upgrading of formerly exported frozen bone-in meat parts, turning them into attractive boneless products. Computer-aided portioning of poultry meat, like with Marel's I-Cut 122, is even more sustainable, as the giveaway is minimal, while increasing the meat value once more.

Even if there are any small leftover pieces of meat, Marel's automation technology can transform this formerly 'waste' into valuable meat mass. This meat mass can serve as a base material for producing convenience foods, further increasing the value of the original meat.

Overall market trends

European poultry processors are continuously looking for highest possible efficiency of their operations, bilaterally connected with the growing consumer demand for poultry products. Marel Poultry has already foreseen the current need for an increased line speed and has set a new benchmark in this respect by introducing 15,000 bph processing.

Sustainability benefits from this growth of efficiency too, since only slightly modified machinery will produce a considerable larger amount of products. This means a significant reduction of energy, water and environmental footprint, compared to a full expansion with a second processing line.

News

Get in touch

Our dedicated team is here to help and answer any questions you may have. Please complete the form, and we’ll get back to you as soon as possible. We look forward to hearing from you.