SensorX Accuro intelligently creates contaminant-free batches of trim with precise fat to lean ratio (CL) and weight targets. The advanced technology behind this user-friendly system ensures that every batch is precisely on target and that trim is used in the most efficient way to optimize its value. Companies processing as little as 1,500 kgs/hour of trimmings have experienced significant financial benefits.

The secret to maximizing trim value

SensorX Accuro: Advanced trim management to increase margins and consistency

Whether you supply and sell trim or create batches for internal further processing, discover how Marel's SensorX Accuro can help you get the utmost value from your raw material. This innovative trim management system increases margins and minimizes lean giveaway while ensuring the highest levels of consistency and food safety.

Start with superior analysis

At the core of SensorX Accuro is Marel's industry-leading X-ray technology. It scans whole muscle and trim with unmatched accuracy to measure the fat to lean ratio (CL) and weight, as well as detect any hard contaminants such as bone, metal and glass.

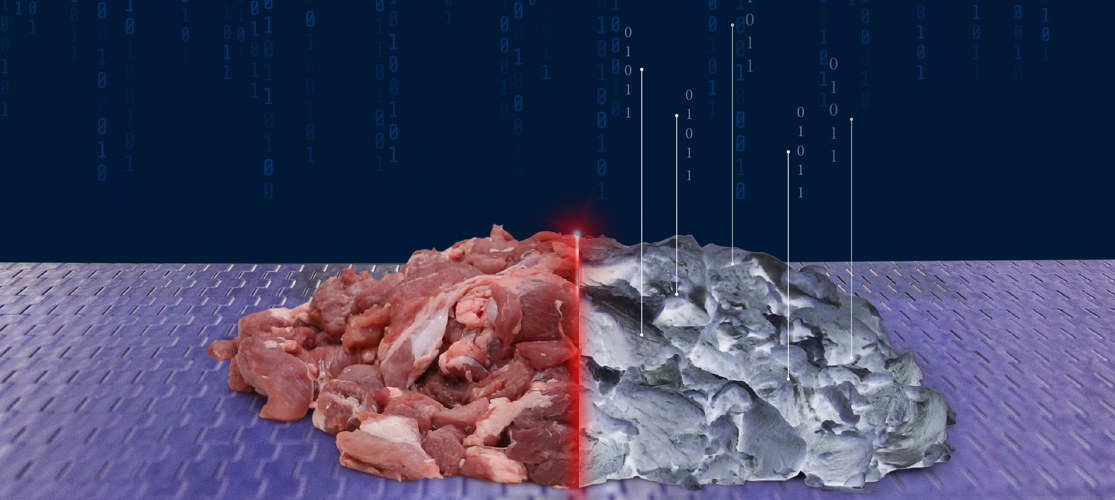

Control to create value

Knowing the precise fat to lean ratio (CL) is beneficial, but controlling how the trim is distributed between final batches is where SensorX Accuro really adds value in a way no other system can. Using sophisticated grading technology, SensorX Accuro determines the optimal allocation of trim to create more of the batches that have a higher value – for example, those with the lowest fat to lean ratio (CL).

The system, which is extremely easy to operate, gives processors an unrivaled level of control, allowing a precise fat to lean ratio (CL) and weight target to be set for each batch. Processors can even specify what types of cut go into which batches. SensorX Accuro's high level of flexibility also allows multiple products with different specifications to be created simultaneously.

Optimize consistency, minimize lean giveaway

The level of accuracy offered by SensorX Accuro gives processors complete confidence that every batch of trim they supply will always meet specific customer requirements. And not just the overarching order specs but down to each and every individual unit. The system can manage the content of each batch so accurately that lean giveaway is kept to an absolute minimum.

Automate to increase accuracy and efficiency

After a simple manual pre-sort, the system fully automates the grading and batching of trim, achieving far greater accuracy than could ever be achieved manually. In addition, throughput and line efficiency are significantly improved. The SensorX also serves as a logistics solution, ensuring a smoother flow from the deboning line to the packed product, which can include bags, 60lbs cartons, creates and combos.

Measure, monitor, improve

Innova food processing software is an integral part of SensorX Accuro. It captures information from the system to enable data-driven decision-making. This data gives an overview of production performance, and by monitoring KPIs such as throughput and contaminant rate, opportunities can be immediately identified to streamline processes and enhance operational performance.

Increase traceability and food safety

With Innova, traceability for food safety is built into every step of the production process, which is an essential element in building and maintaining customer confidence. It ensures processors can provide quality assurance reports and act quickly to minimize the size of recalls and trace every product back to its source.

Protect and enhance your company's reputation

Not only does SensorX Accuro increase the value of your trim and virtually eliminate customer claims for off-spec products, it is also a guarantee to customers that you will always supply safe, high-quality products. This helps maintain the trust of existing customers and can also be an important factor in securing new business.

Your partner for maximizing value

Marel is in the business of transformation, innovation and inspiration. We provide equipment, software, and solutions that help processors maximize the value of their raw material through the use of cutting-edge technology.

Our inspection solutions start with SensorX Omina for flexible trim monitoring. SensorX Magna offers a high-capacity inline inspection solution for superior bone detection and correct fat lean ratio in both fresh and frozen raw material.

Find out how Marel's trim management solutions can help you to get the most from your trim.

News

Get in touch

Our dedicated team is here to help and answer any questions you may have. Please complete the form, and we’ll get back to you as soon as possible. We look forward to hearing from you.