It may be obvious that quite some 2020 stories had a relationship with the Covid-19 pandemic. Market changes and adaptations in modus operandi due to the coronavirus crisis were frequently addressed themes. Here’s the Top-10 of Marel’s stories in 2020:

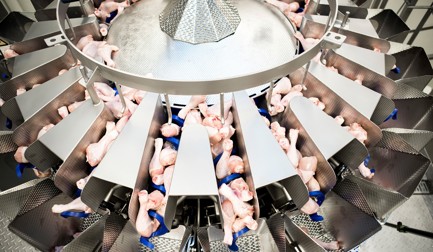

1. Inside Costco’s new chicken operation

The new Lincoln Premium Poultry processing plant in Fremont, Nebraska, is initiated by Costco and is the exclusive supplier for all Costco outlets in western USA. After the startup, LPP gradually grew to processing more than 2 million birds per week by the end of 2020. Marel has almost entirely equipped the processing plant, with highest attention to hygiene and sustainability. The installation includes CAS stunning, an air chilling tunnel, IRIS cameras and RoboBatcher. Read more...

2. Marel fully equips Bell & Evans’ state-of-the-art plant

Marel’s largest project in 2020 was Bell & Evans’ greenfield processing plant in Fredericksburg, Pennsylvania, USA. The Bell & Evans company really makes sustainability statements, hatching organic ‘Klassenbester’ chickens only, and paying high attention to animal well-being. It’s therefore almost logical that the company opted for Marel’s state-of-the-art ATLAS live-bird handling and CAS SmootFlow anesthetization systems. Read more...

3. Why do we need data-driven processing?

The future of poultry processing is on our minds all the time. But the future is already here, since our industry has plenty of data available, ready to be processed into practical information. Marel’s Innova software platform provides all the tools you need for process monitoring, data analysis and continuous improvement. This will be extended to cloud technology, artificial intelligence and the Internet of Things sooner than we all think. Read more...

4. A radical rethink of install and commissioning

The main theme of this article is how to continue installations and service in pandemic times. Hazeldene’s greenfield plant in Australia serves as an example how this succeeded wonderfully. Field service engineers who usually fly around the world, were confined to give remote support, a new development which turned out to become Marel’s routine soon. Read more...