Information

Optimal tempura quality maintained

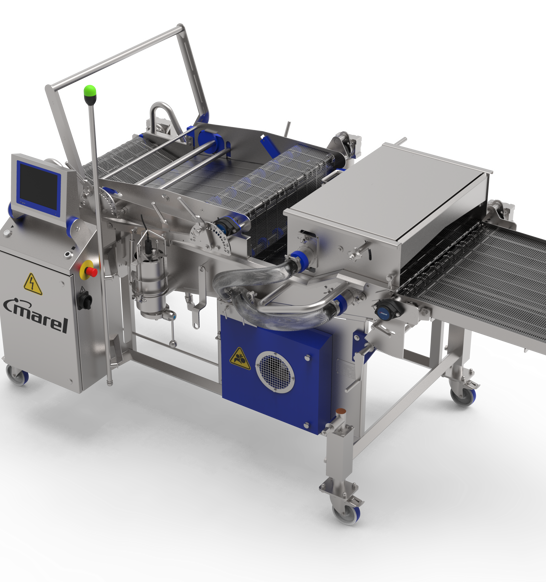

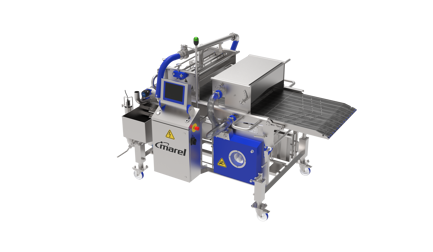

Preventing the loss of leavening agents is key to ensuring a crispy and puffy layer of tempura after frying. The Active Tempura Applicator uses advanced technology to ensure batter quality is optimally maintained during the coating of formed and whole muscle products.

A tank with an innovative insulating jacket keeps the tempura at a consistently low temperature and an exceptionally small buffer ensures batter is refreshed frequently. Agitation during application is minimized to preserve quality even further.

Perfect top and bottom coverage

A conveyor belt transports products gently down through the tempura batter, while a top belt makes sure they are fully submerged. This guarantees all-round coverage however uneven the product surface. When products leave the machine, an air-knife blows off excess batter. Its innovative design ensures equal airflow across the belt to give highly consistent coverage.

Minimal product marriages

The Active Tempura Applicator outfeed belt is separately driven and heat resistant allowing products to transfer directly into the fryer. The angle of the outfeed can be quickly and easily adjusted for a precisely controlled transfer, allowing higher throughput without marriages.

Supporting every step in the process

The Active Tempura Applicator is a crucial step in our full convenience food processing line for creating convenience products such as chicken schnitzels, chicken nuggets and other case-ready coated products.