Information

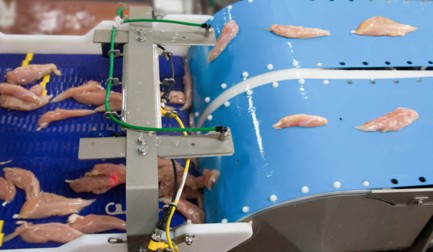

The Automated Tender Line is an integrated automated solution for the consistent production of portioned tenders that can maximize your yields by utilizing intelligent portioning by weight or length. It consists of an automated SingleFeed system, a TenderPositioner, and an I-Cut 122 Trim Sort. The SingleFeed will start the singulation and set throughout, the TenderPositioner will rotate incoming tenders up to 45 degrees in order to achieve your finished product specification and spaces them appropriately so they are in the perfect position for the I-Cut 122. The TrimSort device inside the I-Cut 122 will then remove the “trim” or “off-cut” of the tender from the value stream. This improves grading capability by removing undesired products from the value stream.

Uniform with lowest giveaway

The Automated Tender Line produces uniform tenders, cut to the customer’s specified fixed weight or dimensions. Combining high throughput and impressive reliability, the Automated Tender Line achieves highest added value and saves considerable labor. This automated tender solution is truly a cut above the competition.

A cut above

Marel’s TenderPositioner is an add-on feature to the SingleFeed module where singulation is done with wet products (water chilled or applied water mist). While the SingleFeed singulates bulk items from downstream processing, the TenderPositioner positions tenders for optimal cutting.

The TenderPositioner is an added functionality with low maintenance, excellent cleanability and simple operation. It eliminates the bottleneck area of feeding and styling tenders without the need for extra labor to operate. A true cut above in automation, tender positioning and grading.

Higher productivity

This tender positioning solution realizes approx. 30% higher throughput with 3% higher yield compared to a manual line. The solution provides productivity with a reduction of labor and at the same time, better product quality.