Information

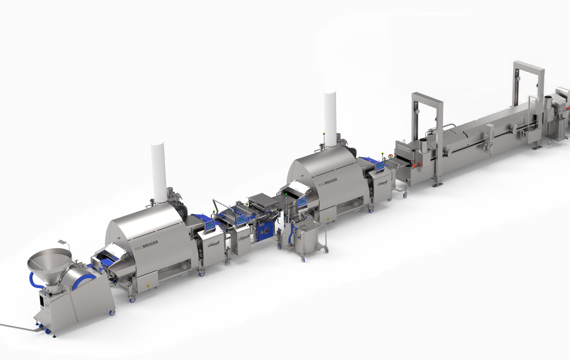

Homestyle chicken wings are very popular products in convenience food environments at home or at the QSR restaurant. Marel has put together a dedicated convenience food line for this type of poultry products. The products that come off the line are excellently prepared and only need a short frying time at home or in the QSR restaurant.

The Homestyle Chicken Wings Line can produce high-quality coated wings in a very consistent and repeatable way. The harmonious interplay between hardware and software ensures the production of convenience products with highest added value.

Pre-dusting

First of all, the chicken wings are marinated in a ValueDrum to get the right flavor. After that, the marinated products enter the RevoBreader for pre-dust coating. RevoBreader in drum mode applies a fine layer of flour (pre-dust) to the product as a basis.

The pre-dusted wings are conveyed to the Active Tempura Applicator where they are dipped into tempura. Excess tempura is removed leaving just the right amount all over the product, which is ready now for the next step.

Flaky appearance

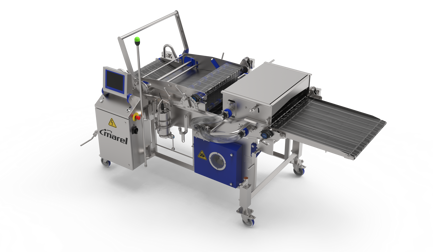

Another RevoBreader in drum mode takes care of the dry coating. This is where the wing coating gets its homestyle character. The RevoBreader makes sure the flour-based breading goes into all crevices of the product. Mechanical force on the product (falling from a height) ensures that the layers of breading accumulate and all the cavities are covered with breading, giving the perfect flaky appearance.

Reduced manual labor

After tumbling in drum mode, the RevoBreader evenly spreads product across the belt, without the need for additional manual handling. This not only reduces labor but also improves the products’ transition into the next processing step. It is also critical to ensure products do not stick together and the delicate layers of homestyle breading are preserved.

Cooking, freezing, packing

Products are now ready to be fried in the GoldFryer. During frying, the coating breaks open giving the product its golden, crispy homestyle appearance. The inside of the products, however, is still raw and needs heat treatment. To get a fully cooked product, the chicken wings go into a ModularOven. In here, the climate can be set for two separate towers, getting juicy products with maximum yield, without compromising food safety regulations.

At the end of the line, the products are frozen and packed according to the desired specifications. Now the homestyle wings are ready for consumption, after being fried shortly at home or in the QSR restaurant.