Information

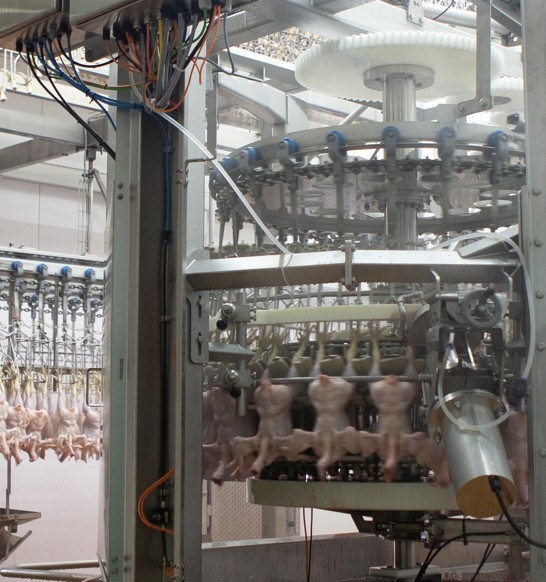

Marel’s LineLink transfer systems have been developed for capacities up to 15,000 birds per hour (bph). The LineLink DE transfers products from the defeathering line to the evisceration line. In addition to transferring each product, all information collected on each product is also conveyed to the next line. LineLink DE’s automatic, labor-free inline transfer helps optimize product hygiene and ensures full traceability.

One-to-one transfer

Both lines run at exactly the same number of shackles per minute. Products are transferred on a one-to-one basis, preventing empty shackles and a higher line speed downstream. This way, products are transferred correctly by both legs and are properly positioned for the next process.

Incoming products are conveyed around the system’s carousel to the point where they are guided into the evisceration shackle. Products are now perfectly positioned for automatic evisceration.

Foot cutter

The LineLink DE includes a foot cutter, which cuts off feet at the tarsal joint. The system enables precise positioning and creates more time for an accurate foot cut. Feet remain in the killing shackle to be unloaded or optionally processed downstream.

An IRIS DF vision assessment system installed in the defeathering line can be an aid to veterinary inspection. The system identifies rejects, which can then be removed from the process automatically by a selective unloader.

Ultra-reliable coupling

Line forces are synchronized electronically by the Marel Active Tension Control (ATC) system. ATC compensates automatically for differing chain stretch on the two lines. This way, both lines always run at precisely the same number of shackles per minute and ultra-reliable coupling can be achieved.

- The LineLink DE transfer system couples lines to run at the same speed

- Developed for processing capacities up to 15,000 bph

- ATC controls synchronization of line forces

- No empty shackles created downstream

- Fast but careful handling with no damage to the product

- Traceability ensured by individual transfer of data with the product

- Foot cutter included

- Optimized product hygiene

- Evaluation of performance possible

- Innova PDS allows for real-time monitoring from a central point

- Optional aid to veterinary inspection with selective, IRIS DF based unloading

- Robust RS frame for ease of cleaning

- Low cost of ownership