Information

Applications

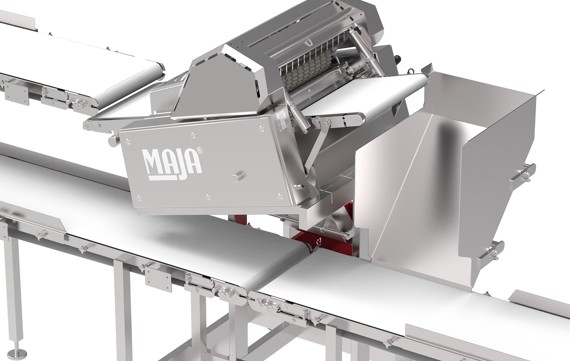

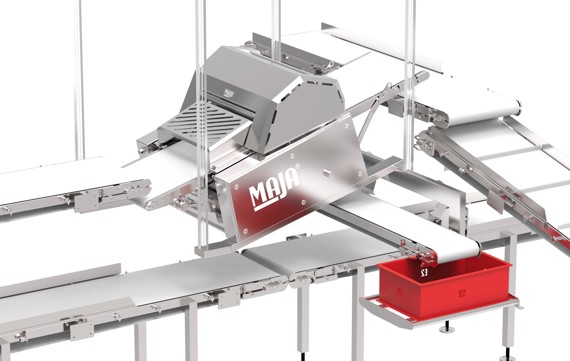

The MAJA BXAplus is designed for conveyorized derinding of all fresh pork cuts, e.g. belly, flank, back fat, neck fat, jowl, shoulder and ham cap, shoulder without bones (also with boneless knuckle), and ham without bones and without topside, etc.

Yield-oriented skinning by automatic cut control and optimum pressure

A mechanical process without the need for photo-electric barriers or compressed air technology ensures optimal positioning of the knife against the meat at the start of the skinning process. This ensures that the maximum amount of rind is removed, and nothing is left behind. Residual rind can be as little as 1%, depending on the type of product and cut, meaning that almost no additional processing is required. This helps to save labor and time and increases the product's quality. As residual rind must not be removed by hand knife, there is less damage to the surface of the product.

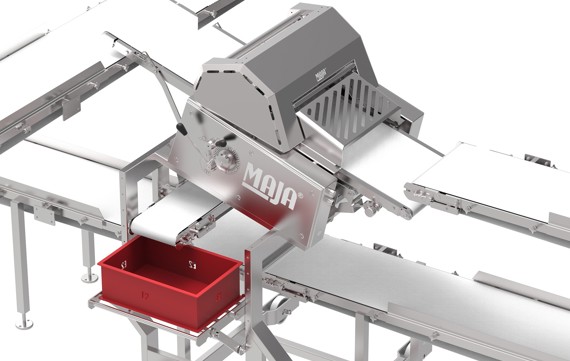

Quick and easy changeovers

The height of the pressure roller can be individually adjusted within seconds, so downtime between products is minimal. The machine’s suspension devices and spring unit can be further adjusted to achieve the best possible pressure settings for each individual type of meat cut.

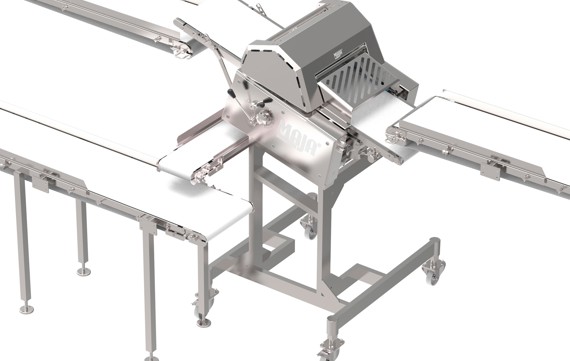

Features

- Highest safety standards

- Easy knife change with quick-locking device

- No removal of the knife holder for cleaning

- Fast and easy cleaning and maintenance

- Meets EU regulation EN 12355

- GS seal of approval for safety, tested by the German body BGN