Information

After the eviscerator, several operations have to be done to prepare the products optimally for chilling and achieve the highest yield for the main product as well as by-products.

In the duck industry, careful handling of the neck and neck skin is crucial for the end product. Marel PMJ uses four machines to ensure the best possible effective neck process: Neck Skin Slitter, Head Cutter & Tongue Harvester, Neck Skin Inspection Machine and Neck Cracker. Performance of this four-stage neck process is independent of the killing method used after stunning. The combined system performs better than any other when it comes to the removal of esophagus and trachea. All neck processes aim to get a higher neck skin yield and better neck skin presentation.

Neck Skin Slitter

Head Cutter & Tongue Harvester

Neck Skin Cleaner

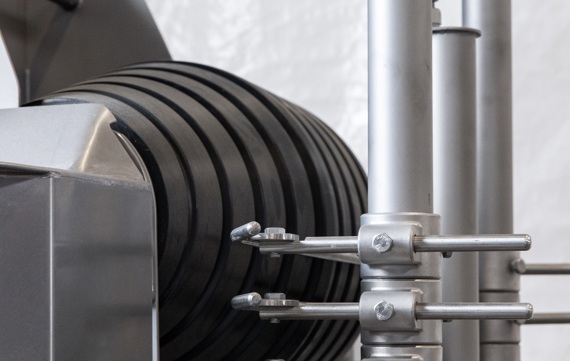

Neck Breaker

Only the neck bone is removed; the cleaned neck skin stays with the product.

Final Inspection Machine

A final carcass check is done by the Final Inspection Machine. It uses vacuum to remove the (remnants of) lungs and other debris from the rib cage area inside. The double-barrel probe allows for independent vacuum cleaning of the left and right cage, assuring an optimal cleaning result. The gentle shape of the tip prevents rib cage damage while applying thorough cleaning. The Final Inspection Machine operates very energy-efficiently, as vacuum is only active when the probes are in cleaning position.