Information

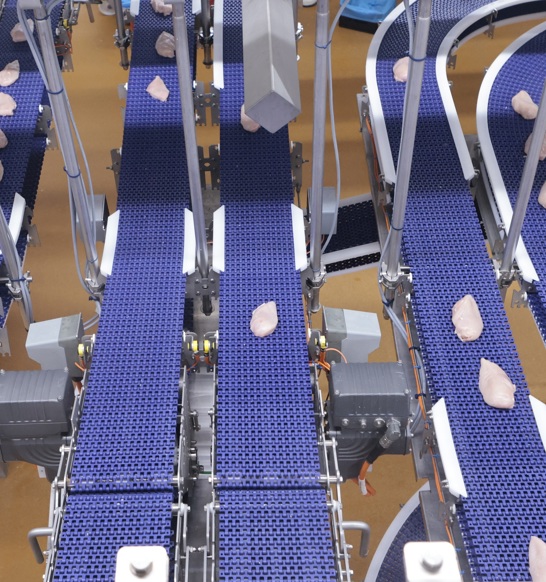

Innova ProFlow Breast Meat software takes control of the entire breast meat process after deboning. Based on data supplied by IRIS FI (quality), SensorX (shape, weight) and sensors along the belt (position), the characteristics and whereabouts of every single fillet are known.

No more separate settings

Before, the necessary weight and quality ranges had to be distributed to the different orders manually. Adjustments to the I-Cut 122 and RoboBatcher had to be made separately. Every new order required a reset of each piece of equipment. That’s a thing of the past now. Applying ProFlow Breast Meat software means having one single point of control without the need to set every individual machine separately. No more worries about optimal weight distribution or about what raw material is coming in.

All-encompassing

Innova ProFlow Breast Meat software pulls all data together. It knows what raw material is coming in, as SensorX and IRIS FI continuously measure the number, weight and quality of incoming fillets. It also sees which flocks are available to generate the fillets and produce the order. Then it calculates which weights and quality grades need to be used for each order to achieve the best performance. The all-emcompassing software even adjusts all machine settings to enable optimal processing. Finally, by means of SystemFlex Distributor belts, it distributes every single fillet to its best destination. This can be the RoboBatcher for retail packs, a bulk dolav, a 10-kilo QSR box or a convenience line. Each order process starts and stops automatically. The result is high throughput, minimal giveaway and optimum utilization.