Information

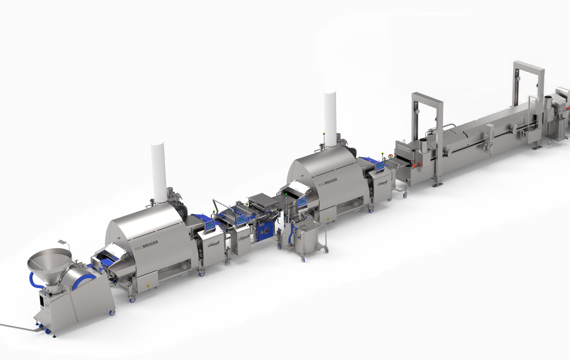

The RevoBreader is a multi-purpose, flexible machine that offers a flatbed mode and drum mode in one enclosure. This dual-mode configurability is the ultimate solution for applying high-quality coating, both to home-style and flatbed coated products.

Switching from one mode to another is easy; it doesn’t require the removal of any machine parts and it takes less than 2 minutes.

Flatbed mode

In flatbed position, RevoBreader guides the products through a bottom bed of crumb, while covering the top layer with crumb gently falling on the product. This results in high quality, uniformly coated products.

In flatbed mode, the Revobreader can also operate as a pre-dusting machine. For such jobs, and for all jobs with fine and free-flowing flour, the optional dust cyclone is available, filtering large amounts of air from the machine. This helps maintain a clean, dust-free working environment.

Drum mode

In drum position, a high pickup of crumb and optimum home-style coverage all over the product is guaranteed, as well as high retention of crumb to the product during the frying process. This is ideal for coating of bone-in products. In a QSR home-style production run, the drum of the RevoBreader completes the coating process. The result is a home-style crumb with a handmade look, a breading with a highly attractive appearance, perfectly suited for sale in QSR restaurants.

Thanks to the large drum size, changing between flatbed and drum position does not require the removal of any machine parts, as the belt can be extended through the drum. Therefore, the changeover time between both positions is less than two minutes.