Information

Trendsetting in poultry batching

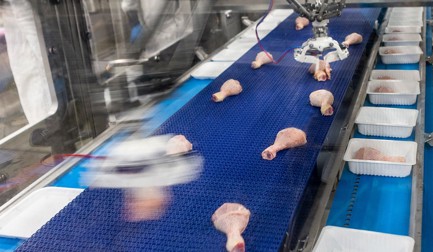

Take your poultry processing into the future with robotics and intelligent software. RoboBatcher Flex is unrivaled in poultry processing. With innovative batching technology and automated processing, your business can reach new levels of optimization and efficiency.

Increase yield, eliminate giveaway

Innovation robotic technology combined with state-of-the-art batching software to pack trays to a fixed-weight virtually eliminating giveaway. Fillets, drumsticks, inners/tenders, or whole legs are scanned and weighed entering the RoboBatcher Flex. Robotic arms select pieces using these precise measurements to pack each tray to the pre-programmed fixed-weight and style. Any pieces out of spec can be by-passed, improving quality control and yield.

Unrivaled speed and accuracy

With a minimum of two robotic arms working in tandem, the RoboBatcher Flex simultaneously packs multiple trays on single or dual tray lines with unprecedented speed and accuracy, processing up to 300 pieces of bone-in or boneless poultry every minute.

When exchanging the fillet gripper for a dedicated tenderloin gripper (a question of a few minutes), the RoboBatcher Flex can also pick and pack those inner fillets.

Improving food safety through automation

The system minimizes manual handling from the packing processes, so you can provide optimal hygiene and food safety while significantly improving processing times to maximize product shelf life.

Intelligent software for ultimate optimization

Innova intelligent software gives real-time reporting for single-skill equipment or full-line solutions. You can make data-driven decisions for optimized processing, increased yield and reduced giveaway. With unparalleled traceability built into every step of the production process, Innova can trace every product back to its source and processors can act quickly to minimize product recall.

Full-line integration

The RoboBatcher Flex can be seamlessly integrated with Marel portioning and grading systems for full-line product utilization and increased profitability. When interacting with the I-Cut 122 portion cutter, it forms ‘a Robot with a Knife’, cleverly deciding which fillet weights best match the order requirements. Instead of cutting all fillets to one ideal average, this concept only cuts what is really needed.