Information

Intelligent batch selection

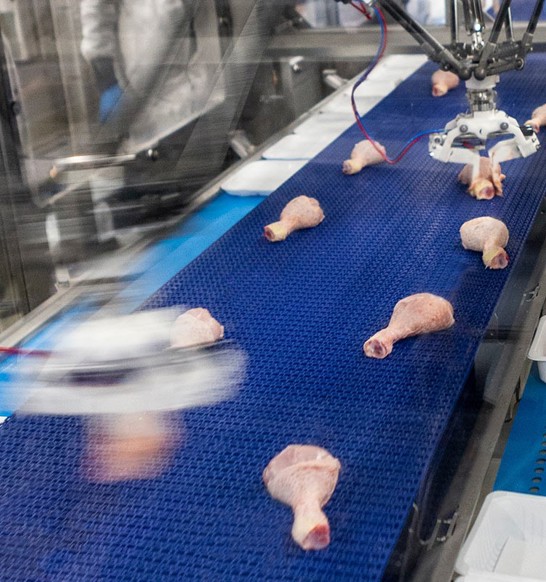

Ideal in line with the ACM-NT automatic cut-up system, the RoboBatcher Flex ensures optimal product utilization with intelligent software that co-ordinates feed from the cut up line with the requirements for each tray. The Innova PDS production management software enables the RoboBatcher Flex to request whole legs or drumsticks of a certain weight and quality at a certain speed from the infeed for each tray. This produces an accurate, perfectly styled tray without any production delay.

Two versions for leg products

Available in two different versions for leg products using either two or three cells, this flexible fixed weight batcher can run two individual tray jobs at the same time. This makes it possible to run separate jobs on left and right leg products if desired. No discharge is needed in this system as the RoboBatcher receives only the legs that it requests for each tray.

Suitable for a vast range of plastic and polystyrene trays

The efficient flight-less high friction belt allows the system to run a wide range of different plastic and polystyrene trays. Seamless tray dispensing is ensured with a built in tray buffer system. Changeover from one type of tray to another is fast and easy.

Complete cut-up and batching line

The RoboBatcher Flex for whole legs delivers optimal performance aligned with the ACM-NT cut-up system. Logistics are fully integrated between system components ensuring the best product distribution available. This production set-up offers flexibility and great product utilization while giving processors complete production control and full operational overview. The Marel Poultry poultry cut-up and batching line delivers high product utilization and excellent batching results with minimum giveaway.

- Request the exact leg it needs for each tray from the cut-up line.

- Can run up to two different batching jobs simultaneously

- Works with a wide range of different plastic and polystyrene trays

- Flight-less high friction belt and a built in tray buffer