Information

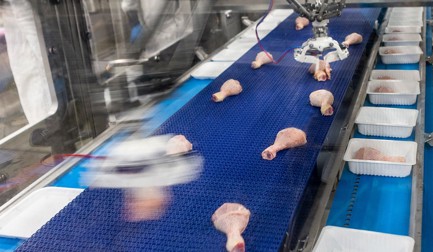

The RoboPacker automates the manual task of packing and styling catch-weight products into trays. It minimizes labor and can increase throughput, improve yield and deliver consistent performance over an entire day. By reducing the number of people involved in the packing process, the RoboPacker also contributes to higher food safety standards.

Full control over the packing process

With its vision unit, the RoboPacker detects the dimensions and position of each product, while also estimating its weight. It processes this data to place the product in trays accurately.

The RoboPacker will style the products in every single tray, offering a range of styling patterns such as yin-yang, fishbone, woven, as well as customer specific. This ensures flexibility and visual appeal, adapting to various product presentation needs. All defined and adjusted easily on the HMI that sets new standards controlling and adapting the machine to fit our customers' needs.

Perfect companion

With the capacity to handle up to 180 pieces and 80 catch-weight trays per minute, the RoboPacker is the perfect companion for a packing machine, feeding it with PE, polystyrene, flatboards and more. The RoboPacker has a small footprint, thus optimizing the workspace while enhancing performance. Depending on production size, either a single-cell or dual-cell RoboPacker will be required.

Gripper technology

Any request to pick, pack and style specific poultry products can easily be met with RoboPacker’s extensive portfolio of grippers. Product changeovers are easy and quick; exchanging the gripper takes just minutes. This allows for seamless adaptation to various products, from chicken breast fillets over drumsticks to tenders.

The supreme gripper technology is optimized to handle poultry products and contribute to the immaculate styling of the trays, which reduces labor dependency.

Minimum target weight

In principle, the RoboPacker produces count-job trays, all with the same number of pieces in each tray. However, the system can ‘weigh’ too; the vision unit can estimate the weight of each piece by a volumetric calculation. Therefore, the RoboPacker can also pack on “minimum target weight”. If a tray job that involves packing three pieces has already reached its minimum target weight with only two pieces, the RoboPacker will finalize that tray with those two pieces.