Information

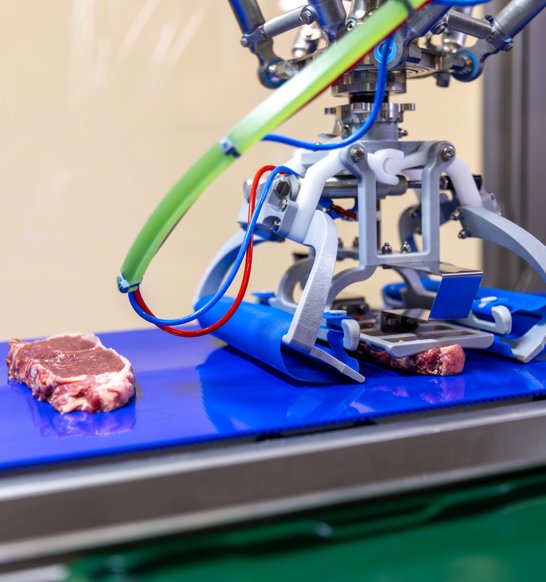

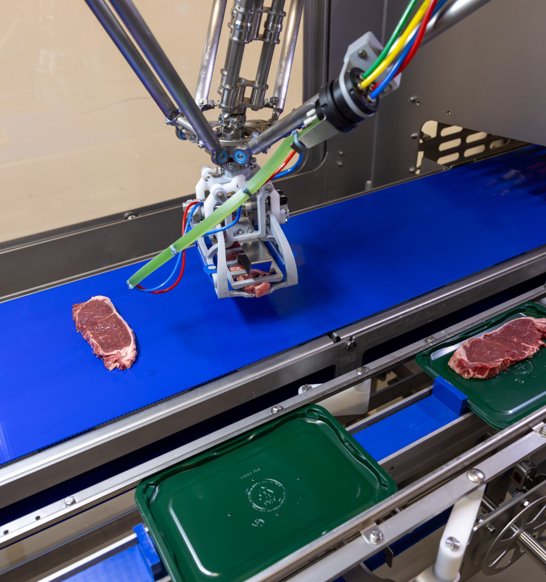

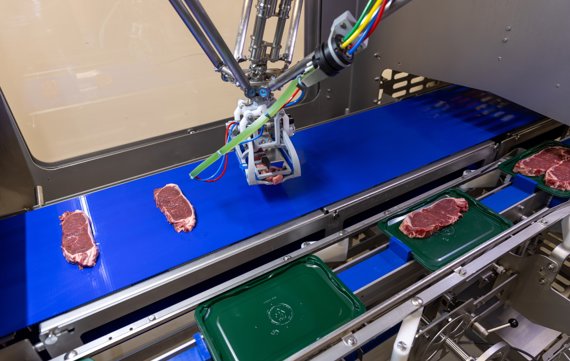

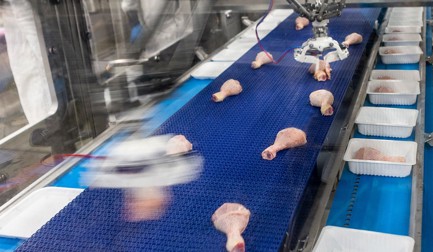

RoboPacker automates the packing and styling of catch-weight products into trays. It reduces dependency on manual labor, increases throughput through consistent performance 24/7 and improves food safety. The RoboPacker conveyor system transports trays and protein portions side by side, it can pick and place up to 90 pieces of protein per minute with a single robot and carry up to 80 trays per minute.

More control over the packing process

A 3D vision unit scans each product as it enters. The robot utilizes the data collected on dimensions and position to pick and place each product in the corresponding tray to a predefined styling recipe. Through volumetric calculation the vision unit estimates the weight of each product, enabling ‘minimum weight target’ packing, providing even greater flexibility to your line. The easy-to-use HMI screen sets a new standard in control. Operators can choose from a range of styling patterns, or define, adjust and adapt the RoboPacker to meet their presentation needs.

Perfect companion

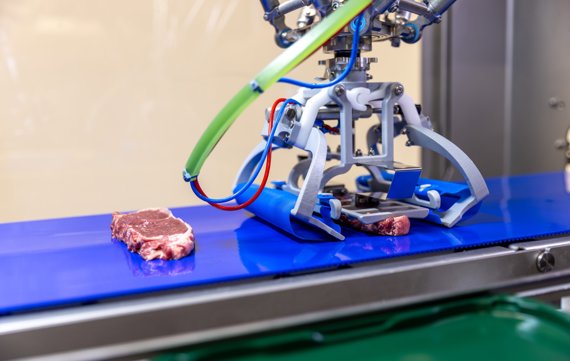

The RoboPacker’s custom tray handling interface ensures it can seamlessly integrate with tray dispensers and operates with a wide variety of tray formats including PE, polystyrene, flat-boards and more. Available in single or dual cell configurations to suit any production size, the small footprint of this compact machine allows it to fit into most production lines with ease. The single cell configuration of the RoboPacker is specifically designed for meat processors to pick and place single steaks in the perfect position every time.

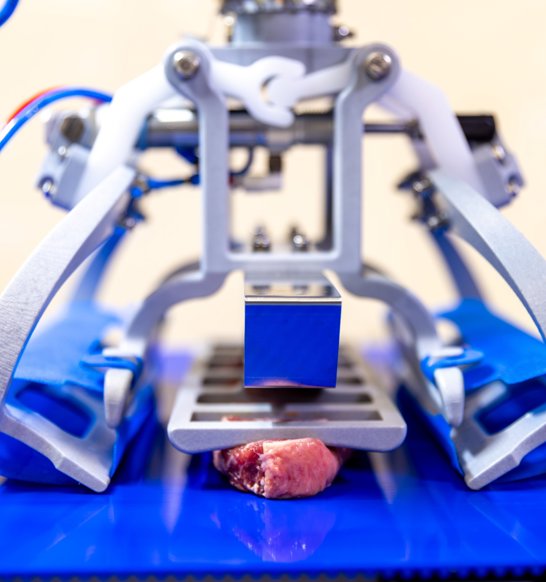

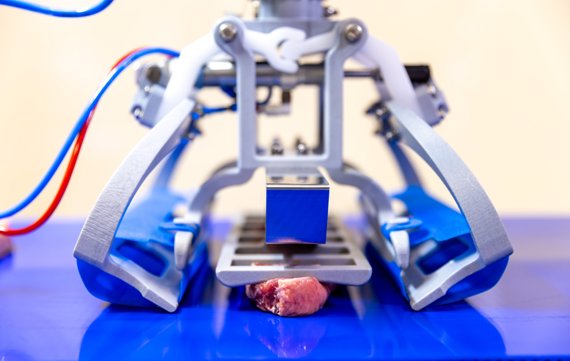

Gripper technology

A variety of grippers are available to meet the needs of different proteins. The gripper designed for single-portion proteins such as steaks, provides efficient and secure product handling. Even during fast movements, the product remains centered and stable. The design minimizes parts to facilitate cleaning and increase hygiene.