Information

Deheading with Vision technology

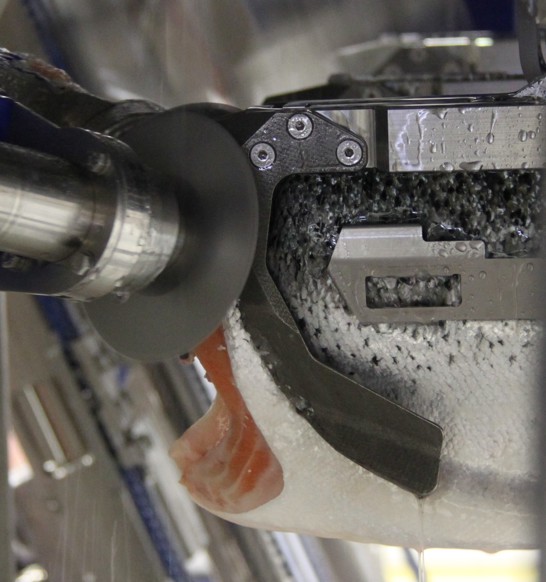

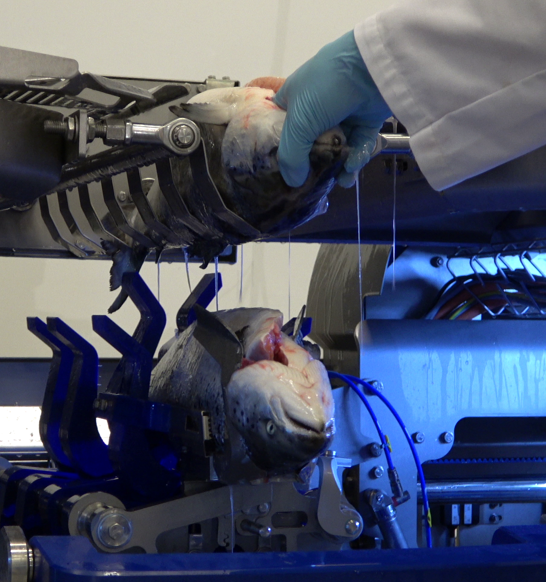

The Salmon Deheader MS 2721 V enables efficient and accurate deheading with the maximum yield on every fish. The fish is measured before each of the cuts (neck, shoulder and tail) to achieve the best cutting result. Before the v-cut, a vision camera registers the head’s position and the knives are automatically positioned to make the best cut along the collarbone.

Easy infeed with on-screen support

The fish is slid into the preloader at the infeed station with one hand and dropped into the carrier. To assist the operator a screen shows the accuracy of the fish’s position, enabling the operator to adjust the fish’s placement and optimize the performance.

Automatic transfer to filleting

When connected to the Marel Filleting Machine MS 2730, the deheaded fish can be transferred directly from the Deheader to the Filleting Machine, eliminating the need for manual infeed into the filleting machine, ensuring a more consistent infeed and improving the flow of the line.