Information

Ultra-low pressure forming

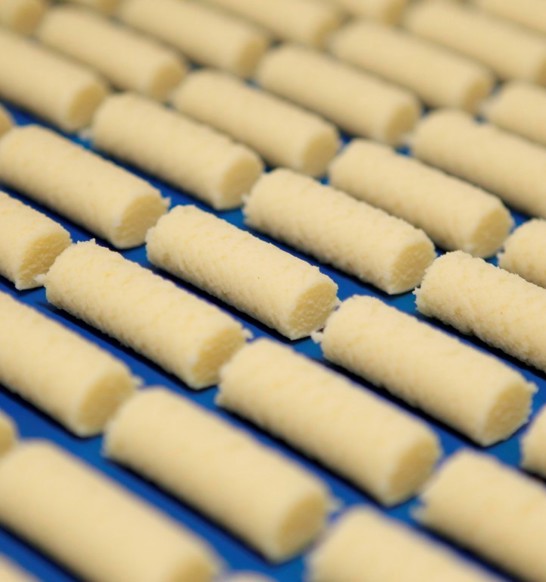

Products such as potato duchesse, rösti, croquettes and pommes noisettes are formed at ultra-low pressure, ensuring the texture and structure of the potato mass is retained and that every product has consistently uniform shape and accurate weight.

Multiple product possibilities

Interchangeable forming units let you create multiple product shapes. The units are quick and easy to change, giving you a highly flexible production process, which allows you to easily meet changes in consumer or seasonal demand.

Higher volume – high throughput

The TEX-10 can easily connect to the Extruder, Diaphragm, Pommes Duchesse Unit, and RevoPortioner, giving you an excellent solution for high-volume, low-pressure portioning. The RevoPortioner not only lets you increase throughput, it also opens up even more product opportunities. It can portion your potato mass into virtually any shape you desire whilst ensuring that each product is consistent in weight and appearance.