Information

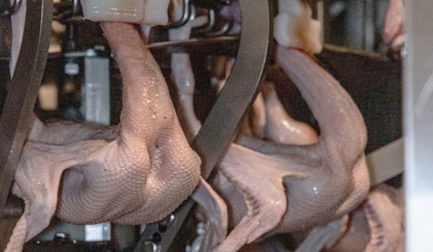

Skin presentation of duck meat products should be perfect. Products should naturally be feather-free without skin damage. The waxing process takes care of this. After plucking, Marel PMJ’s unique Three Point Suspension System automatically suspends the heads in the middle slot of the shackle. This prevents wax from entering the beak. Now products are ideally positioned for a short dip in the hot Wax Immersion Tank, to prevent overheating. After this, products are submerged in the Cooling Basin, allowing the wax layers to cool down quickly and solidify for easy removal. Now the heads are released again and the product, suspended by its legs only, is ready for optimal wax removal. The Wax Remover peels the solidified wax, including down and pin feathers.

Wax Immersion Tank

Marel PMJ's Wax Immersion Tank conditions the wax for an optimal distribution of wax onto the product. Each individual tank benefits from accurate temperature control. The system allows a very short dipping time, preventing product overheating. The heated connection bridge prevents an unwanted build-up of wax, while double-plated insulated walls and floor result in reduced energy consumption.

Cooling Basin

Marel PMJ's Cooling Basin is positioned after the hot wax dipping tanks. Products that have just been dipped in hot wax will be submerged in the Cooling Basin to allow the wax-layers to cool down quickly and solidify for easy removal. This is done with air agitated water, which improves heat dissipation. Throughout the basin, the temperature of the water remains the same; an optional heat exchanger allows for even more accurate temperature settings.

Head Release Machine

Marel PMJ's head release machine fully automatically unloads the heads of the product from the middle slot of the shackle in a fully automatic way. In this way the product is suspended by its legs only and prepared for an optimal wax removal.

Wax Remover

Marel PMJ's Wax Remover removes the solidified wax from the products. During this gentle, but effective peeling process, remaining down and feathers come loose with the wax layer. The Wax Remover features adjustments for speed, height and angle to enable the processing of a wide range of waterfowl products. Guard plates ensure a channeled discharge of the wax flakes.

Hock Wax Remover

Marel PMJ's Hock Wax Remover specializes in peeling the solidified wax from the bird's hocks. This difficult area requires dedicated treatment. The Hock Wax Remover has the same features as the Wax Remover.