Paper records are slow and inefficient, meaning critical insights can be buried in stacks of paperwork. Without real-time visibility into key processes like inventory management and sanitation procedures, the risk of contamination increases. And when a crisis arises—like a recall or contamination issue—the last thing anyone wants is to waste valuable time digging through files.

Paper systems also leave too much room for human error, making it difficult to ensure accurate, audit-ready documentation. And as food safety regulations evolve, staying compliant with stringent standards like FDA, HACCP, and ISO becomes increasingly challenging.

To ensure food quality and remain competitive in today’s food safety environment, processors need the speed and insight that only food manufacturing software can provide.

| Reason for food recall |

How AXIN Software and digital solutions help |

| Ineligible import |

|

| Undeclared substances / allergens |

- Integrated inventory and recipe management system with allergen control

- Automated end-of-line labeling verification

- Compliance monitoring

|

| Bacterial contamination |

Rapid lot identification system ensures:

|

| Foreign material |

Solutions like SensorX bone inspection systems combine advanced equipment with digital solutions to detect and reject hard contaminants like bone, metal, and glass in poultry, meat, and fish. |

How can food production software improve safety and quality?

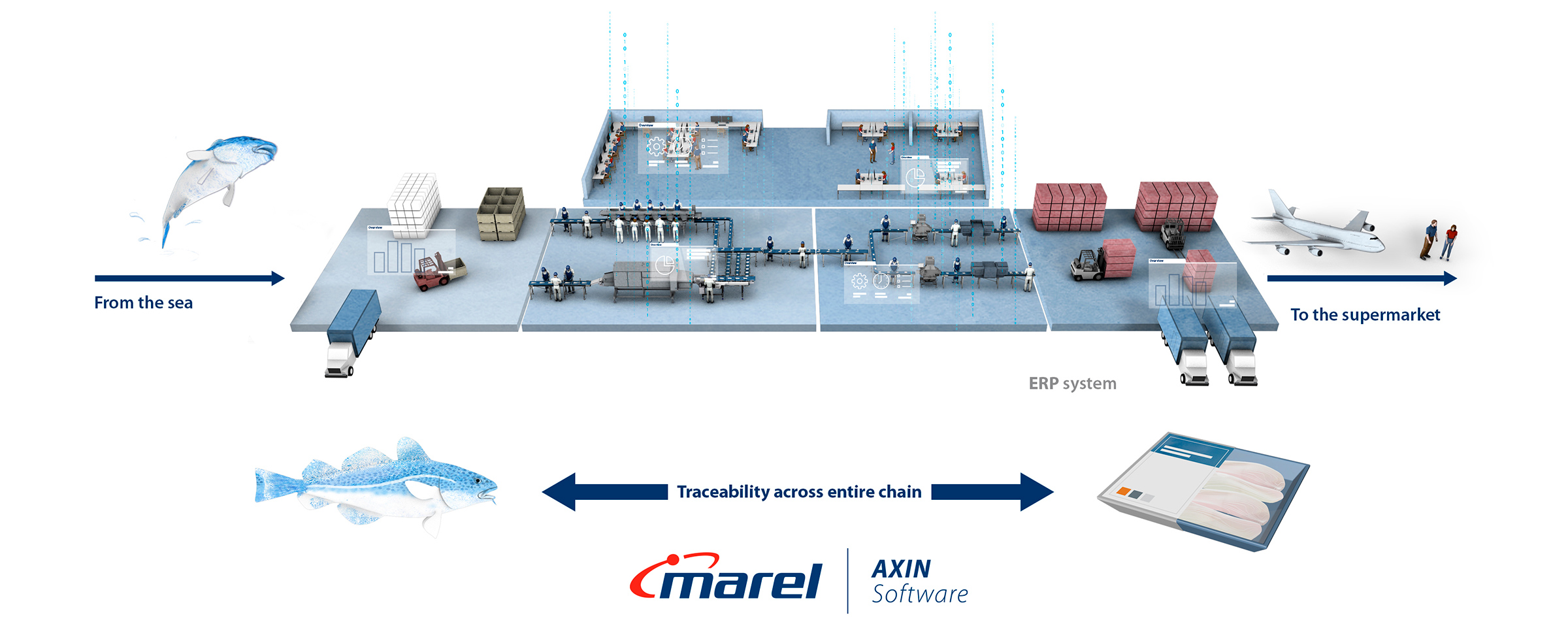

For key roles such as QC managers, food safety officers, and compliance teams, ensuring food safety while keeping up with regulatory demands is a constant challenge. Marel offers a wide range of AXIN Software Solutions designed to streamline these responsibilities, make work more efficient and effective, and ultimately enhance food safety and quality at every stage of food processing.

Real-time data analytics and control

AXIN Software can analyze data with a level of speed and interconnectedness that is impossible with paper. Real-time data analytics alert to potential problems and highlight opportunities for improvement, so QC managers can make informed decisions in an instant via a user-friendly dashboard. The software can also analyze historical trends to provide insights that inform a strategy of continuous improvement.