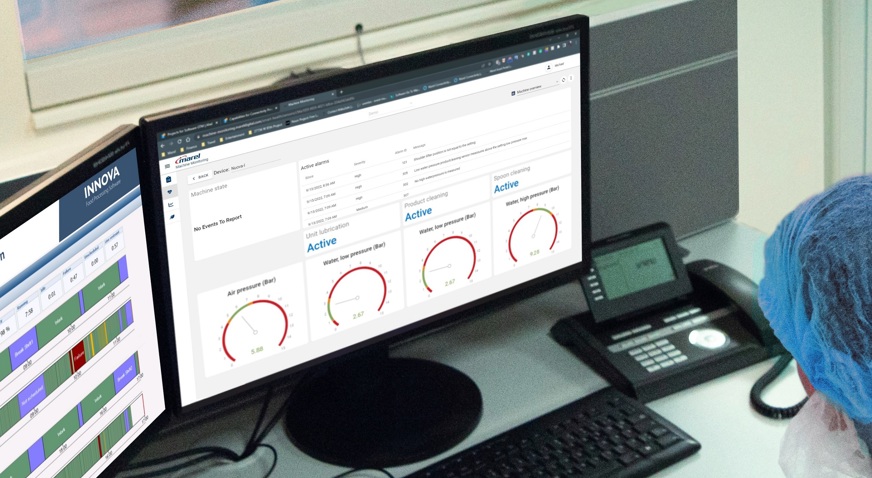

HMI control

Even though these i-machines are advanced, they are easy to operate. The HMI (Human-Machine Interface) touchscreen is very straightforward to use and requires little training. Half an hour’s instruction will do. Controlling the machine digitally, backed by SmartBase software, is about choosing ‘recipes’. Operators no longer adjust levers or hand wheels. Instead, they control the i-machines via the HMI. It shows a control menu with recipes that are pre-installed by JBT Marel or the poultry processor and are based on historical data gathered per flock. The recipes define the specific processes for a variety of flocks. Changing settings between flocks poses no problems. With a single tap on the screen, the i-machine will remember previous successful flock settings.

The display also provides overviews of machine health and performance and can issue alerts.

Automatic adjustments

The digital recipes, which take flock anatomy into account, are responsible for setting the machine. This eliminates the need for manual adjustments based on guesswork or gut feeling and reduces the risk of human error when setting the machine. With a few simple presses on the screen, all (or most) adjustments of the machine are set in their optimal way to handle the specific characteristics of the incoming flock of birds. Is it a flock of heavy broilers? Then, with a press of a screen button, the machine settings will adjust themselves to handle the large dimensions. Like this, each flock will be processed in a dedicated fashion, ensuring a higher yield.

When concept chickens with longer legs come in, the recipe adapts height or guides accordingly. Product Technologist Eva van der Velde explains, “Every operator knows what to do. When a heavy flock arrives, you simply select the right recipe on the touchscreen. The machine settings then adjust themselves. When light birds come in, you press the small-chicken icon to activate the corresponding settings; it is as simple as that. This works wonderfully. Performance stays incredibly stable.”

![System.Collections.Generic.List`1[Marel.Core.Models.ImageAltText]](/media/mbthvlic/eva-nuova.jpg?rxy=0.7407108417652362,0.29691612980668586&width=69&height=69&v=1dc43583e08f630)