Information

Wide range of fillet products

The AMF-i produces a wide range of breast fillet products for retail and industrial customers. It also harvests valuable by-products, ensuring that downgrading is kept to a minimum, and profits can be maximized.

Consistently high yield

The AMF-i accepts a wide variety of even non-calibrated breast cap dimensions. Due to its advanced levels of intelligence, it can cope with a variety of incoming products, ensuring fillets produced are of consistently high quality and yield.

Accurate measurement of incoming products

The intelligent measurement unit of the AMF-i system automatically detects the changing dimensions of incoming products. Module settings can be adjusted accordingly, resulting in adaptive filleting.

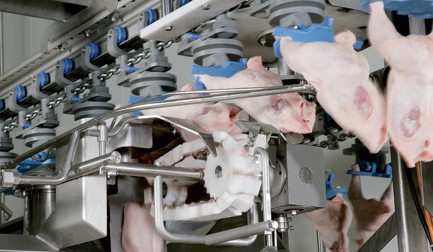

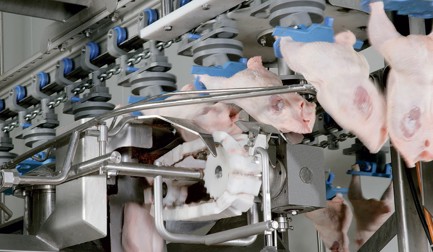

Automated processes

Breast caps of different sizes are automatically positioned onto the product holders by means of the FlexLoader. The holders then convey the products through the system’s modules, placing them into the correct position for each step. All filleting operations can be done automatically, reducing the need for labor. The harvesting process is completed by a visual inspection stage and trim possibility, ensuring the required quality.

Heavy duty

Responding to the global trend of broilers getting bigger, AMF-i is suitable for today's and future heavy weight ranges. The adaptive FlexLoader (standard on all AMF-i versions) is adjustable for different weight ranges.